Bags & Fashion Accessories Quality Control

Experience the confidence of flawless fashion. Our third-party inspection services specialize in detailed quality control for bags and fashion accessories, combining expertise and precision to ensure every seam, stitch, and style meets the highest industry standards.

Bags & Fashion Accessories Quality Inspection Services

As a leading third-party inspection company, we specialize in providing comprehensive quality control services for the bags and fashion accessories industry. Our expert team understands the unique needs and challenges of fashion products and delivers thorough inspection services including material verification, design compliance, dimensional accuracy, workmanship quality, and packaging integrity.

By applying advanced inspection methods and standardized procedures, we ensure each product meets international standards and specific market and customer requirements. We help your brand maintain consistent quality, strengthen market competitiveness, and deliver a reliable product experience to your customers.

Key Inspection Points for Bags & Fashion Accessories

This includes detailed verification of material quality to ensure fabrics, leather, and hardware meet durability and safety requirements. Construction and craftsmanship are evaluated by inspecting stitching, seams, bonding, and fastenings for structural integrity. Color consistency and colorfastness are verified to ensure long-term aesthetic performance.

Dimensions and design accuracy are verified against client specifications, and functional tests are performed on zippers, clasps, and other hardware. Packaging and labeling are examined to ensure compliance with brand standards and regulatory requirements.

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packaging

- On-Site Tests

A. Appearance & style

During third-party inspections of bags and fashion accessories, inspectors verify that the appearance, style, and color of finished products match the client’s approved samples and specifications. Each product is visually checked for overall design, shape, workmanship, surface finish, logos, hardware, and consistency to ensure it meets quality and brand requirements.

Pantone color cards are used as the standard reference for accurate color matching when applicable. When necessary, inspections are conducted under different lighting conditions to identify color deviation, shading, or uneven dyeing, reducing the risk of color inconsistency before shipment.

B. Material

Material verification involves confirming material type, quality, and conformity with client specifications. Based on approved specifications or confirmation samples, inspectors conduct visual and tactile inspections to verify correct materials (leather, fabric, metal, etc.) are used. When required, chemical test reports or appropriate instruments are used to verify material composition and compliance.

Inspectors also perform durability and performance evaluations to ensure materials meet intended usage requirements. This may include wear resistance, tear resistance, and colorfastness testing. For bags, this may include zipper durability and fastener strength testing. For fashion accessories, additional tests may include wrinkle resistance and dimensional stability after washing (when applicable).

C. Workmanship (Construction & Craftsmanship)

C1. Sampling (AQL Sampling Method)

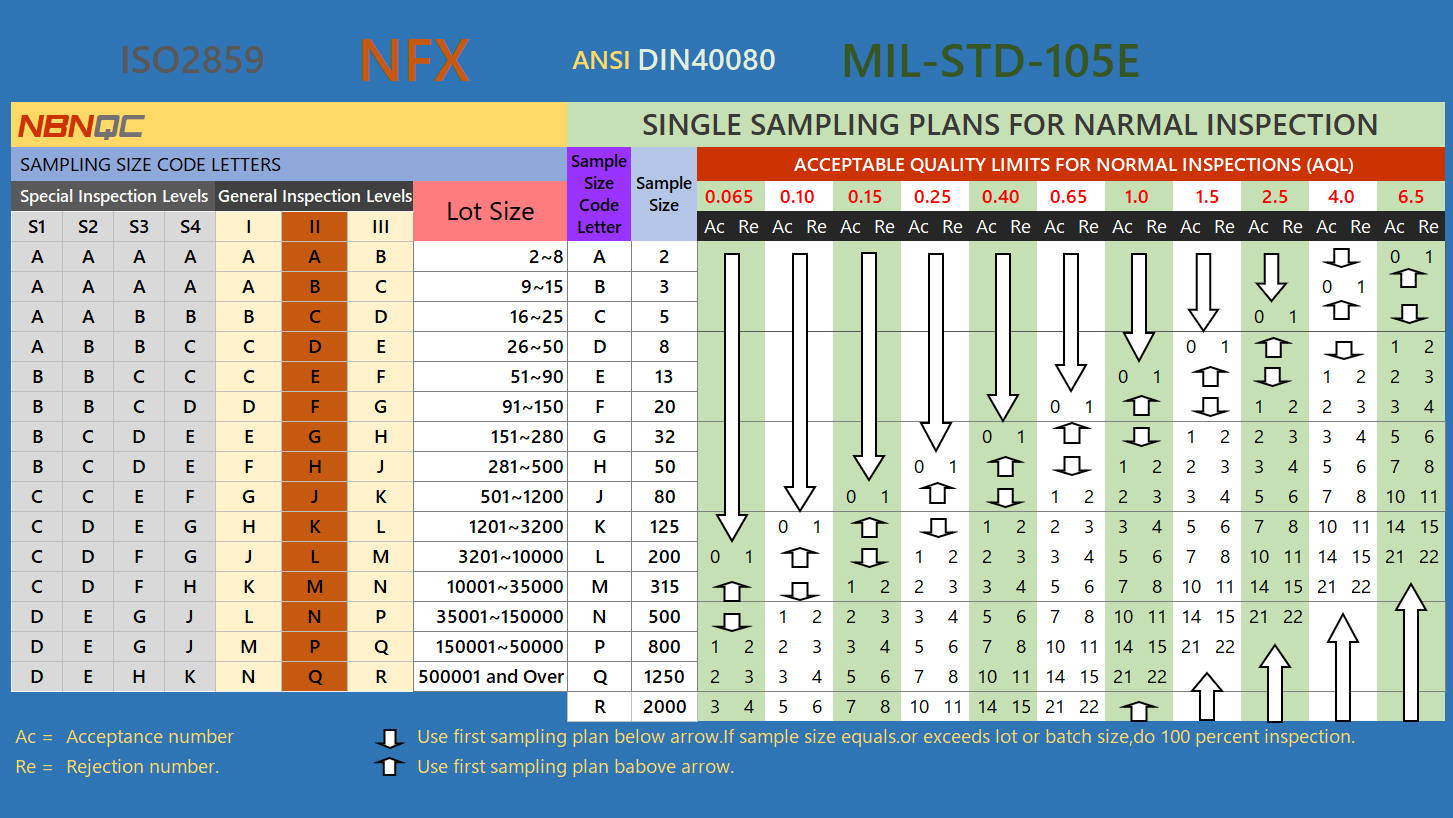

The number of samples is determined based on the client’s inspection level and total lot size, in accordance with international AQL (Acceptance Quality Limit) standards.

For reference, when Inspection Level II and AQL 0 / 2.5 / 4.0 apply, sample size and acceptance limits are determined according to the AQL sampling table. If defect quantities exceed acceptance limits, the shipment will be rejected.

(Default: Inspection Level II, AQL 0 / 2.5 / 4.0 unless otherwise specified.)

This sampling method ensures objective and internationally recognized evaluation of product quality consistency.

C2. Quality Inspection & Defect Sorting

Each sampled product is inspected individually. All detected defects are identified, photographed, and classified based on severity. Defects are counted and summarized to determine whether the shipment complies with approved AQL limits.

For bags and fashion accessories, inspectors focus on:

- Stitching consistency and seam strength

- Edge finishing and trimming quality

- Reinforcement at stress points (handles, straps, corners, zipper ends)

- Hardware installation and durability (buckles, zippers, rivets, magnetic snaps)

- Surface appearance, alignment, and symmetry

- Functional performance and assembly integrity

Final defect statistics serve as the primary basis for shipment acceptance or rejection.

C3. Defect Classification for Bags & Fashion Accessories

D. Size Measurement & Dimensional Accuracy

Measurement specifications are provided by the client, including dimensional tolerances and measurement methods. Inspectors measure selected samples according to the approved size chart and sampling quantity.

For bags and accessories, this may include:

- Overall length, width, height, and depth

- Strap length and adjustability range

- Handle drop height

- Pocket dimensions and opening sizes

- Thickness and capacity-related dimensions

If any discrepancy is identified between the approved size chart and supplier specifications, it is promptly confirmed with the client before final evaluation.

E. Label & Logo Verification

Bags and fashion accessories often involve multiple labels and branding elements, such as:

- Brand logos and embossing

- Hang tags and barcode labels

- Care labels or material composition labels

- Country of origin markings

- Compliance labels (when applicable)

Inspectors verify accuracy, placement, spelling, barcode consistency, and attachment quality of all labels and logos. Each variation is documented with photographs to ensure traceability and brand consistency across product styles and colorways.

F. Packing & Packaging Inspection

Packaging is inspected according to client packaging specifications and shipping requirements. Inspectors verify:

- Outer carton strength, cleanliness, and stacking integrity

- Shipping marks, carton labeling, and barcode accuracy

- Inner packaging materials (polybag, dust bag, tissue paper, inserts)

- Protection against moisture, dust, and deformation

- Presence of desiccants, silica gel, or protective liners when required

- Carton sealing quality and palletization (when applicable)

For polybags or protective bags, inspectors also check puncture resistance, sealing integrity, and suffocation warning compliance when applicable. Proper packaging ensures product protection during transportation and warehouse handling.

G. Common On-Site Tests for Bags & Fashion Accessories Inspection

- Carton Assortment Check

- Carton Drop Test

- Functional Test

- Load Test

- Colorfastness Test

- Color Shading Check

- Adhesion Test

- Odor Check

- Barcode Scanning Test

- Fitting Test

- Metal Detection Test

- Stuffing Material Check

- Waterproof Test

- Fabric Weight Test

- Fatigue Test

- Wear Test

- Pull Test

- Symmetry Check

- Bend/Flex Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.