Electrical & Electronics Quality Control

NBNQC is not only an expert in inspection but also your reliable partner in the global supply chain. We are committed to providing precise and professional quality control and inspection services for international brands and buyers in China.

Electrical & Electronics Quality Inspection Services

NBNQC focuses on every critical stage of the production process—from incoming material verification and in-process monitoring to final random inspection and functional testing. Our experienced inspectors can intervene at key production milestones and conduct on-site checks using standardized procedures and appropriate testing equipment.

We tailor inspection plans to each client’s product type, market requirements, and destination-country regulations. This approach helps ensure your electrical and electronic products meet safety, performance, and compliance expectations before shipment.

Key Inspection Points for Electrical & Electronics

Electrical and electronic products require strict control over component compliance, assembly quality, functional performance, and electrical safety.

Typical inspection scope includes:

- Appearance & Color Consistency

- Dimensional Verification

- CDF (Construction Data Form) Check

- Workmanship (AQL Sampling & Defect Sorting)

- Label & Logo Verification

- Packing & Packaging Inspection

- On-site Tests (Performance & Safety)

A. Appearance & Color (and Dimensional) Verification

Inspectors conduct a comprehensive visual inspection to confirm overall appearance quality, surface condition, and color consistency. Products may be grouped for comparison across batches, and color can be checked against approved references (such as color standards or Pantone cards) under appropriate lighting conditions.

Dimensional verification includes overall length, width, and height, as well as key product-specific dimensions such as cable length, connector size, mounting hole distance, or any size-related requirements stated in the client’s specification or user manual. This ensures the product matches the approved design and production requirements.

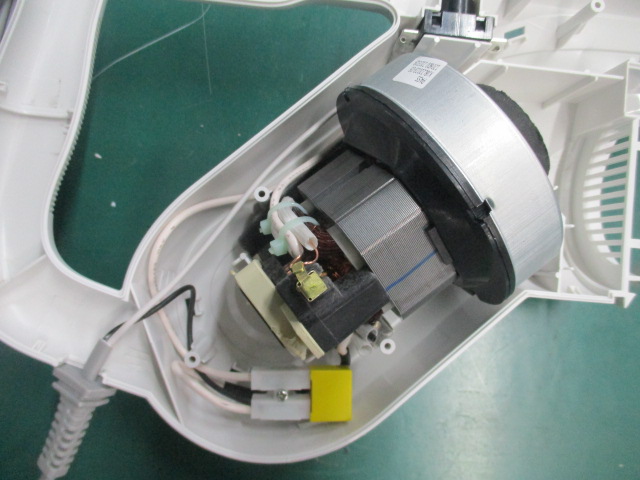

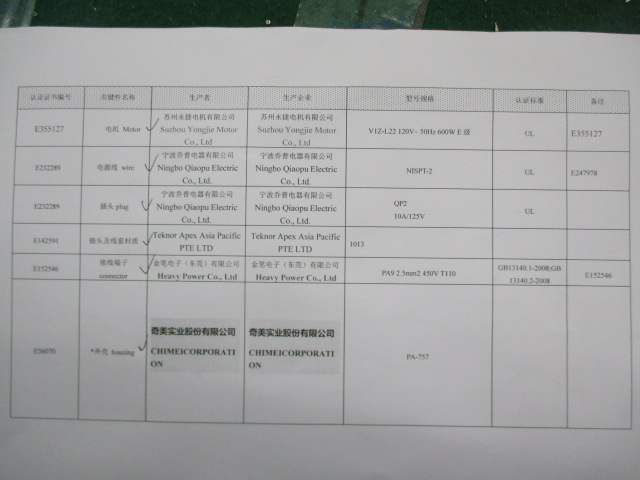

B. CDF Check (Construction Data Form)

A CDF check helps confirm that the product is built according to approved specifications and that key components meet safety and compliance requirements. This step is especially important for products requiring regulatory approval or safety certification.

B1. Document Verification

Inspectors confirm the CDF is the correct version and includes complete information such as component models, specifications, and listed manufacturers.

B2. Component Cross-Checking

Key components listed in the CDF are cross-checked with the actual product, including part numbers, manufacturer details, and key specifications.

B3. Compliance Verification

When required, inspectors review component certifications and test reports to confirm compliance with applicable standards and destination-market regulations.

B4. Supplier / Origin Verification

If component origin is critical, inspectors verify supplier/manufacturer information matches the CDF.

B5. Discrepancy Reporting

Any mismatch between the CDF and the actual product (e.g., different part numbers, manufacturers, or non-compliant components) is recorded and reported for client decision-making.

C. Workmanship (AQL Sampling & Defect Sorting)

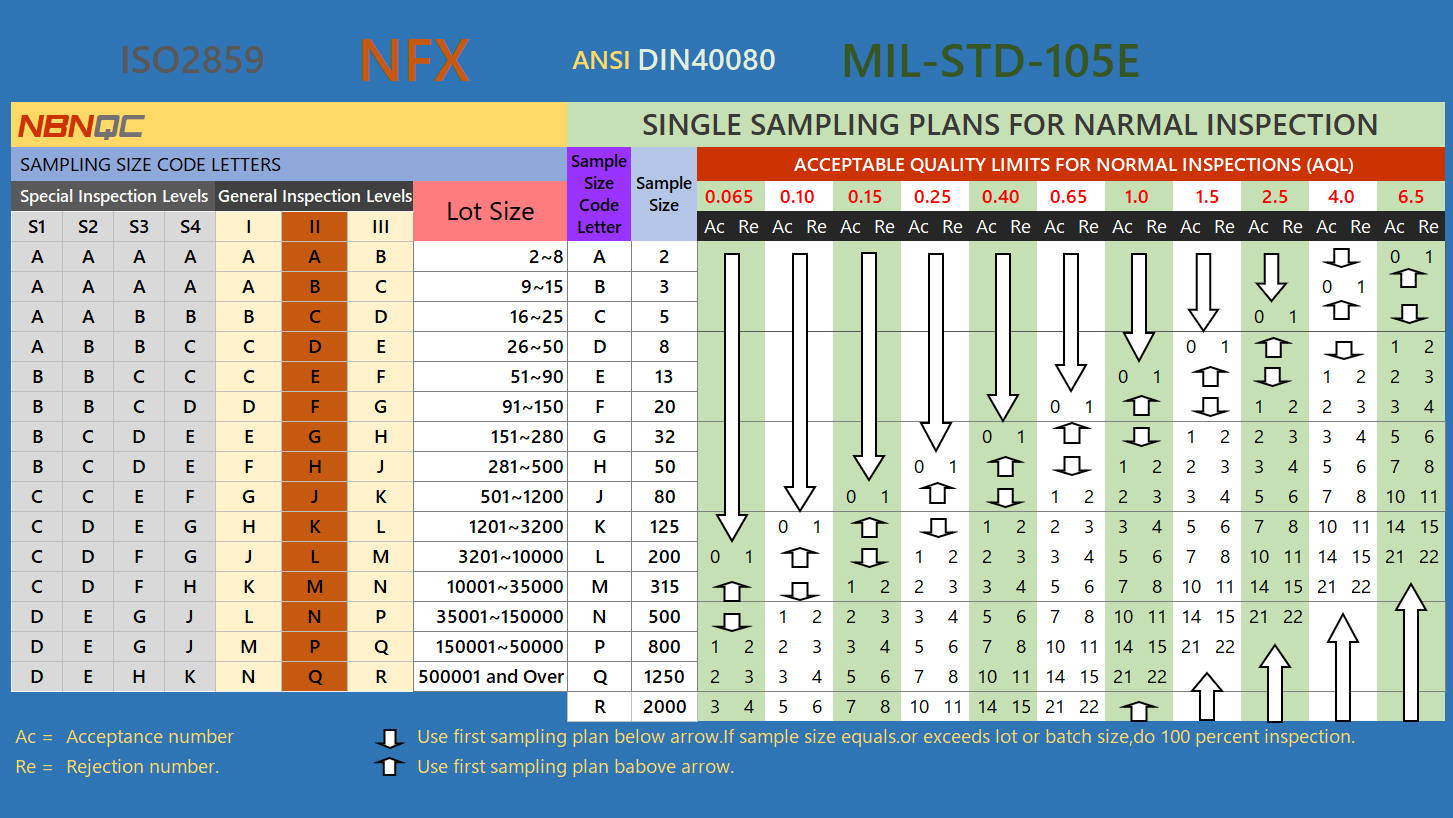

C1. Sampling (AQL Method)

Sample quantity is determined based on the inspection level requested by the client and the total lot size, in accordance with international AQL (Acceptance Quality Limit) standards.

Default: Inspection Level II, AQL 0 / 2.5 / 4.0 (unless otherwise specified).

C2. Quality Inspection & Defect Recording

Each selected sample is inspected individually. Inspectors check assembly quality and workmanship, such as:

- Soldering / welding quality

- PCB layout and component installation

- Cable routing and strain relief

- Screws, fasteners, and housing fit

- Sharp edges, burrs, loose parts, or abnormal gaps

- Overall structure and finishing quality

All defects are identified, categorized, photographed (when needed), and counted to determine whether the lot complies with AQL acceptance limits.

C3. Defect Classification (Electrical & Electronics)

D. Label & Logo Verification

Inspectors verify that labels and logos are correctly positioned, legible, and free from smudging or misprinting. They also confirm that key information—such as safety warnings, ratings, instructions, and compliance marks—matches the client’s requirements and aligns with applicable standards and regulations.

E. Packing & Packaging Inspection

Inspectors verify shipping marks on export cartons, packing methods, accessories, instruction manuals, and inner box printing to ensure they match client requirements. Packaging condition is checked for carton strength, sealing quality, completeness, and protection performance.

Proper packaging ensures product protection during transportation and warehouse handling.

F. Common On-Site Tests for Electrical & Electronics Inspection

Test items vary by product type and client requirements. Common checks include:

- Capacity / battery check (when applicable)

- Functional test

- Fatigue test (switch/button/cable where applicable)

- Hi-Pot test (dielectric withstand)

- Earth continuity test

- Power consumption test

- Internal safety check (basic safety structure)

- Stability test (when applicable)

- Rub & adhesion test (printing/label)

- Pull test (power cord / connector)

- Carton drop test

- Barcode scanning test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.