Footwear Quality Control

We are committed to providing our global clients with the highest standard of footwear quality inspection services. From athletic shoes to fashion footwear and professional work shoes, our expert team ensures that every step of the production process meets international quality standards.

Footwear Quality Inspection Services

As a professional footwear inspection service provider, we ensure the highest quality standards for global clients. With a deep understanding of local manufacturing practices and international quality requirements, our experienced inspectors assess every key aspect of footwear production. From material verification to final inspection, we conduct comprehensive checks to ensure each shipment meets your expectations.

Key Inspection Points for Footwear Products

Footwear products should be aesthetically pleasing, comfortable, and durable. This requires high-quality materials with good longevity, breathability, and appropriate softness for fabrics and leather. Workmanship—especially stitching and bonding—must be durable and free from obvious visual defects. In addition, sizing must follow the approved design and shoe last specifications to ensure proper fit. NBNQC’s footwear inspection services help ensure products meet consumer expectations and applicable industry regulations.

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packaging

- On-Site Tests

A. Appearance & style

Inspectors verify that the footwear design conforms to the approved samples and product specification sheets. This includes evaluating overall shoe structure and key design elements such as heel height and profile, upper construction (stitching, perforations, seams, overlays), toe shape, outsole pattern, and functional/decorative components including laces, eyelets, logos, and trims.

The inspection focuses on accurate positioning, secure installation, dimensional consistency, and visual alignment of all components to ensure the finished footwear matches the intended design and workmanship standards.

Color conformity is assessed by comparing main and secondary colors against approved standards, reference samples, or color charts under appropriate lighting conditions. Inspectors also evaluate color uniformity, checking for shading variation, fading, uneven dyeing, or visible color inconsistencies across different shoe parts and between pairs.

B. Material

Inspectors verify that all materials used in the footwear comply with approved product specifications and client requirements. This includes verifying upper materials (genuine leather, textiles, or synthetics), outsole and midsole materials (rubber, EVA, PU, or composites), as well as lining, insoles, and reinforcement components.

Each material is evaluated for key physical and functional properties, including surface quality, thickness consistency, flexibility, elasticity, abrasion resistance, and overall durability.

For leather materials, inspectors additionally assess grain uniformity, surface finish, color consistency, gloss level, and visible defects such as scars, scratches, wrinkles, or coating imperfections to ensure both appearance quality and long-term performance meet expectations.

C. Workmanship

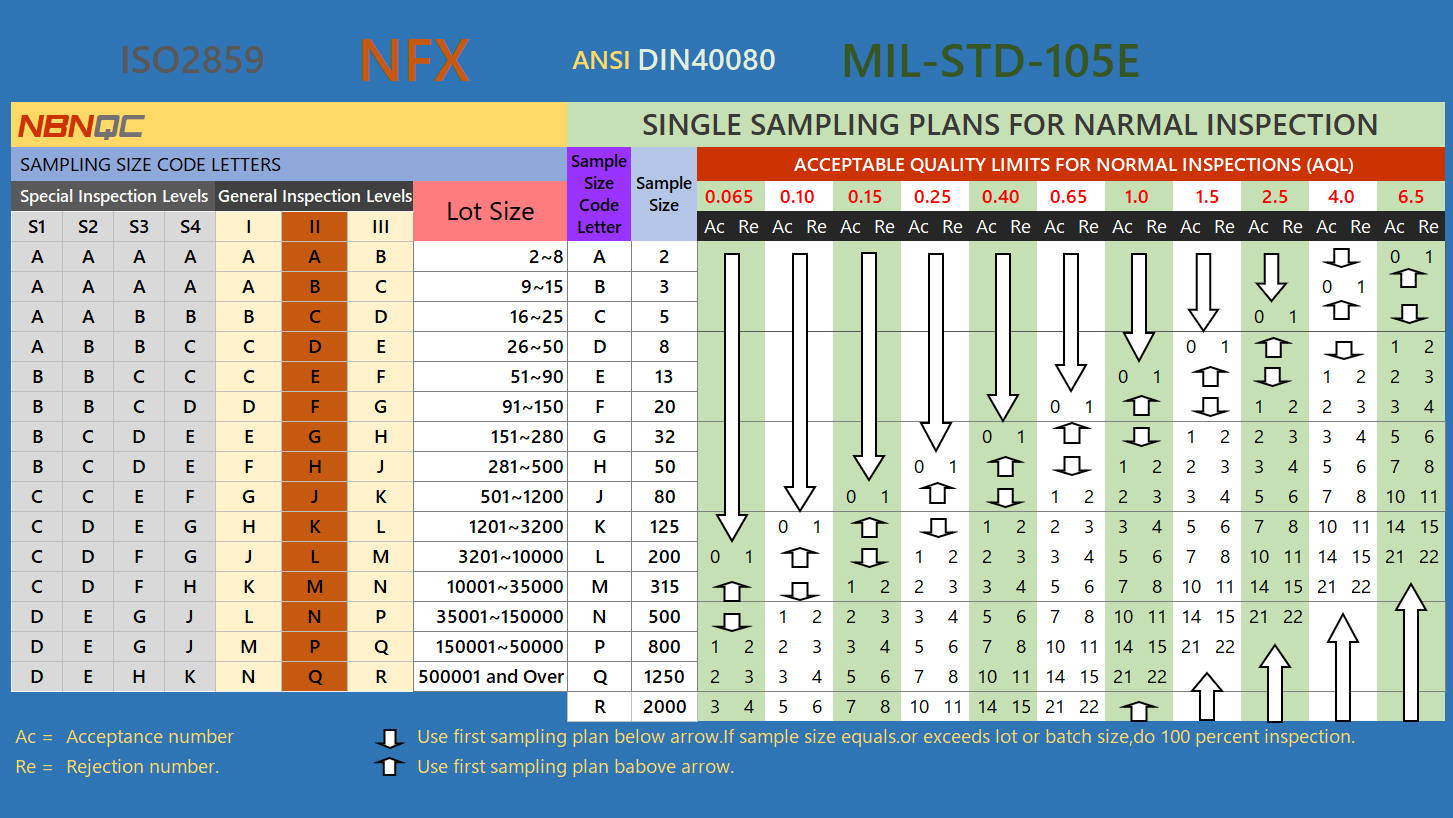

C1. Sampling

The number of samples is determined based on the client’s inspection level and the total lot size, in accordance with the applicable AQL standard.

For reference, when Inspection Level II and AQL 0 / 2.5 / 4.0 apply, sample size and acceptance limits are determined according to the AQL sampling table. If defect quantities exceed acceptance limits, the shipment will be rejected.

(Default: Inspection Level II, AQL 0 / 2.5 / 4.0)

C2. Quality check

Each selected footwear sample is individually examined for workmanship and overall quality. Inspectors assess stitching quality, bonding strength, component alignment, finishing quality, and overall structural integrity.

All identified defects are recorded, categorized, and quantified based on severity. The results determine whether the shipment complies with the specified AQL and serve as the basis for acceptance or rejection.

C3. Defect Classification for Footwear

D. Size Measurement (Footwear Dimensional Verification)

Measurement specifications are typically provided by the client, including size standards, last dimensions, insole length, outsole length, width, and tolerance requirements. Inspectors perform measurements according to the approved measurement chart and the required sample quantity.

If any discrepancy is identified between client requirements and supplier specifications, inspectors will promptly report and confirm with the client before final evaluation.

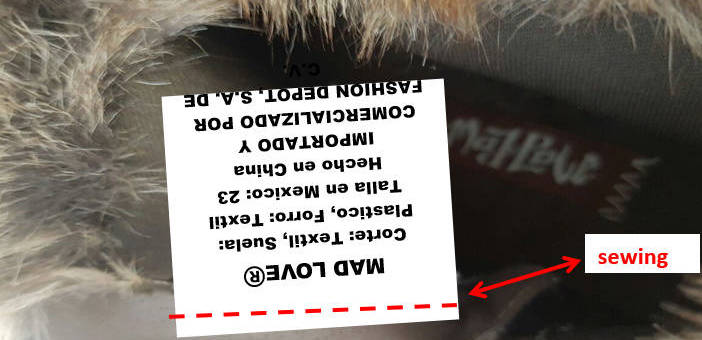

E. Label & Logo

For footwear orders, labels and logos may vary by size, model, color, and production batch. These may include shoe box labels, size stickers, barcodes, country of origin markings, care instructions, and brand logos on the product or packaging.

Inspectors verify the accuracy, consistency, placement, and readability of all labels and logos against client requirements, and document findings with clear photographic evidence.

F. Packing & Packaging

According to client packing specifications, inspectors verify shoe box condition, carton strength, shipping marks, packing method, quantity per carton, and inner packaging quality.

Additional checks include polybag integrity, moisture protection, desiccant placement (when required), carton sealing quality, barcode accuracy, and overall packaging protection to ensure footwear is well protected during transportation and storage.

G. Common On-Site Tests for Footwear Inspection

- Carton Assortment Check

- Wear Test

- Pull Test

- Symmetry Check

- Bend/Flex Test

- Color Shading Check

- Colorfastness Test

- Odor Check

- Barcode Scanning Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.