Furniture Quality Control

From raw material assessment to final product inspection, our comprehensive quality control approach ensures that your furniture not only meets aesthetic expectations, but also delivers long-term durability, safety, and consistent quality throughout the entire supply chain.

Furniture Quality Inspection Services

NBNQC offers specialized furniture quality control services, tailored to each client’s specific requirements. Our experienced team of quality engineers and inspectors conducts comprehensive Factory Audits, Initial Production Inspections, During Production Inspections, and Pre-Shipment Inspections to ensure consistent quality and reliable performance throughout your furniture supply chain.

Key Inspection Points for Furniture Products

Key inspection points include evaluating structural durability and stability, identifying defects in materials and workmanship, verifying dimensions and alignment, and ensuring compliance with applicable safety and environmental regulations. Inspectors also assess aesthetic quality — including surface finish and color consistency — and verify the functional performance of all moving parts.

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packaging

- On-Site Tests

A. Appearance & Style

Inspectors carefully evaluate furniture design elements by comparing selected samples against approved samples or client specifications. Key factors such as color accuracy, proportions, decorative details, surface finish, and overall visual balance are examined to ensure the furniture reflects the intended design and meets customer expectations.

Proper Lighting Conditions: Color inspection should be conducted under adequate lighting conditions. Natural daylight is preferred whenever possible. When artificial lighting is used, light sources that closely simulate daylight are recommended, as different lighting environments (daylight, fluorescent, incandescent) can affect color appearance and consistency.

B. Material

During furniture inspection, inspectors conduct a detailed assessment of all raw materials — including wood, metal, plastics, upholstery fabrics, foams, coatings, and hardware components — to verify compliance with approved specifications, quality grades, and applicable standards.

Key material attributes such as strength, durability, thickness, surface treatment, moisture resistance, corrosion resistance, and environmental compliance are evaluated to ensure the materials are suitable for the intended product use and service life. Where required, inspectors also check material consistency across production batches and confirm that no unauthorized substitutions have been used.

This material verification helps minimize structural risks, prevent premature wear, reduce safety liabilities, and ensure long-term product reliability for international buyers.

C. Workmanship

C1. Sampling

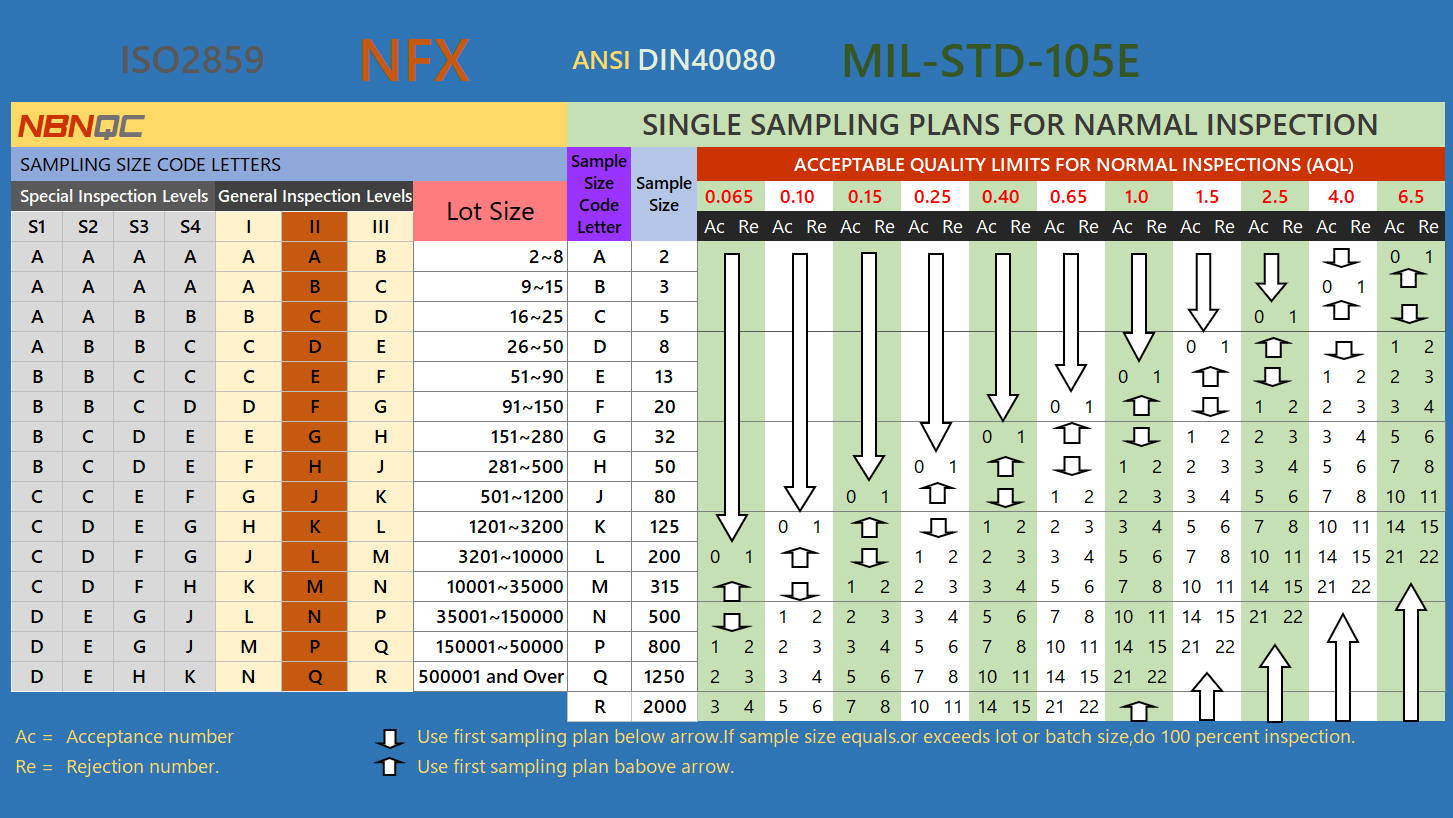

The quantity of samples for inspection is determined based on the requested inspection level and the total lot size, following internationally recognized AQL (Acceptance Quality Limit) standards. For example, under Inspection Level II with an AQL of 0 / 2.5 / 4.0 and a lot size of 5,000 pieces, 200 units will be randomly selected for inspection.

Acceptance criteria define the maximum allowable number of defects (Critical: 0 pcs / Major: 10 pcs / Minor: 14 pcs). If defect quantities exceed these limits, the shipment is classified as failed.

(Default standard: Inspection Level II, AQL 0 / 2.5 / 4.0.)

C2. Quality check

Each selected sample is individually examined to identify workmanship defects, functional issues, cosmetic imperfections, and assembly inconsistencies. All defective items are isolated, classified, photographed, and recorded.

Defect quantities are then statistically evaluated against the AQL acceptance limits to determine whether the production lot meets shipment approval requirements.This process provides an objective and data-driven basis for shipment release, conditional acceptance, corrective actions, or rejection decisions.

C3. Classification of Defects in Furniture

D. Size Measurement

Inspectors use calibrated measuring tools such as tape measures, rulers, calipers, and gauges to verify overall dimensions, internal clearances, and structural symmetry.

Length, width, height, depth, thickness, and critical functional dimensions are checked against approved drawings and specification sheets to ensure compliance with tolerances, assembly accuracy, and end-user usability.

E. Label & Logo

Inspectors verify that all labels, logos, markings, and product identification elements are correctly positioned, clearly printed or embossed, and securely attached according to client specifications and regulatory requirements.

Information accuracy is checked, including brand name, model number, country of origin, material composition, care instructions, safety warnings, and compliance markings. Label durability and legibility after handling and packaging are also assessed.

F. Packing & Packaging

Packaging is inspected to ensure sufficient protection against impact, compression, moisture, and vibration during transportation and storage. Inspectors evaluate carton strength, inner cushioning materials, corner protection, wrapping quality, and palletization methods.

Packaging dimensions, weight limits, stacking method, and labeling are verified to match shipping requirements and logistics standards. Proper handling marks, barcodes, and shipping labels are confirmed for traceability and safe transportation.

G. Common On-Site Tests for Furniture Inspection

- Humidity Test

- Stability Test

- Load Test

- Burrs and Sharp Corners Check

- Function Test

- Carton Drop Test

- Barcode Scan Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.