Garment & Apparel Quality Control

NBNQC provides customized quality control services specifically designed for global apparel brands, ensuring that their products meet all quality requirements and related standards at every step of the supply chain.

Garment & Apparel Quality Inspection Services

At NBNQC, our experienced team of quality engineers and inspectors delivers professional quality inspection services for apparel manufacturers, brands, and buyers worldwide. Our comprehensive apparel quality control program includes Manufacturing Audits, Pre-Shipment Inspections, During Production Inspections, and Initial Production Inspections.

Each service can be tailored to meet specific project requirements, ensuring a flexible, efficient, and reliable quality assurance approach across your apparel supply chain.

Key Inspection Points for Garment & Apparel Products

This includes thorough evaluations of material quality, construction and workmanship, size and fit, design and color accuracy, labeling and packaging, safety compliance, and overall appearance and finish.

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packaging

- On-Site Tests

A. Appearance & style

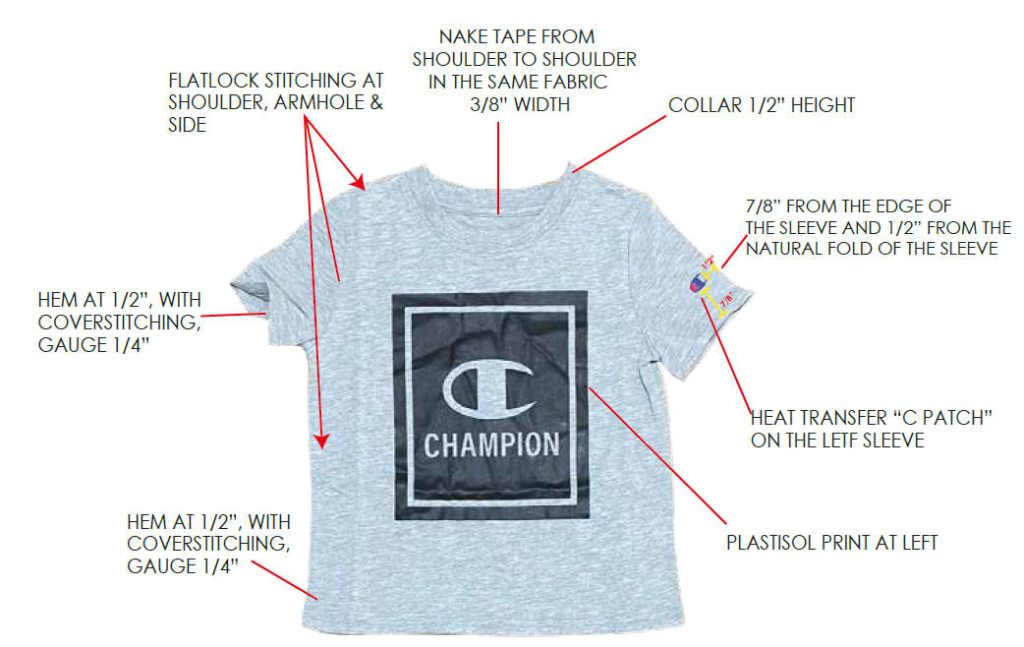

A1. Visual Assessment

Inspectors conduct a thorough visual examination of the garment to verify alignment with the approved design specifications. They check the style, color, patterns, and overall appearance, including print accuracy, embroidery quality, embellishments, and finishing details, to ensure the product meets the intended design requirements.

A2. Comparison with Reference Samples

Inspectors compare the garment against approved reference samples or prototypes. This step ensures that the finished product faithfully replicates the approved style, structure, color, and decorative details. Any deviation from the approved sample is documented and reported for corrective action.

B. Material

The client typically provides detailed specifications for fabrics and accessories (such as buttons, zippers, and decorative items). Inspectors conduct visual and tactile inspections on randomly selected samples and compare them with approved samples to verify material consistency and quality.

When required, inspectors request suppliers to provide third-party material test reports. By reviewing these reports against the client’s specifications, inspectors verify that the materials comply with quality and safety standards.

C. Workmanship

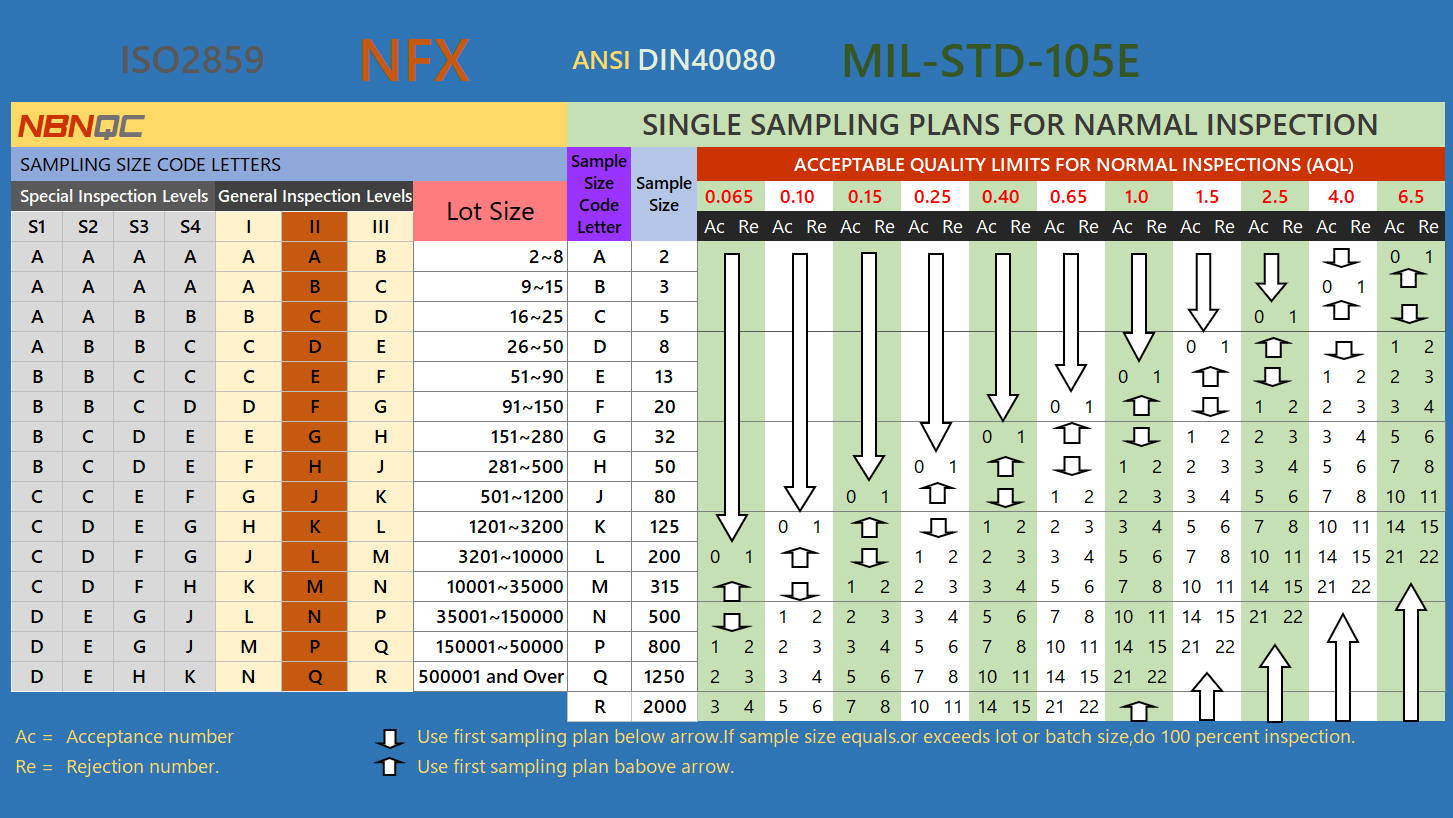

C1. Sampling

The number of samples for random inspection is determined based on the inspection level requested by the client and the lot size of the shipment, in accordance with international AQL standards.

(Default: Inspection Level II, AQL 0/2.5/4.0)

C2. Quality check

Each selected sample is individually examined, and all defective units are identified and segregated. All defects are categorized and quantified based on severity. The final result determines whether the shipment falls within the AQL acceptance limits and forms the basis for shipment approval or rejection.

C3. Classification of defects in garment

D. Size Measurement

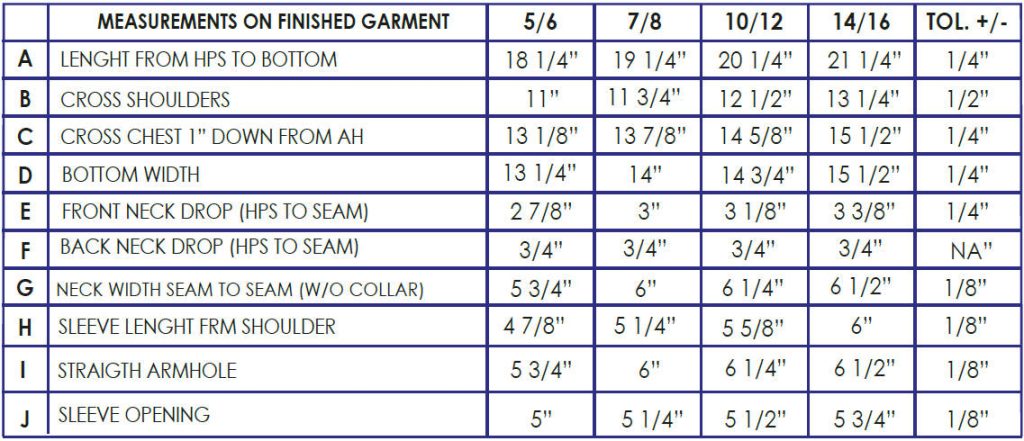

Measurement charts are provided by the client, and inspectors perform measurements based on the specified measurement points and sample quantity. If any discrepancy is identified between the supplier’s chart and the latest approved chart, confirmation will be obtained from the client promptly. Measurement tolerances are evaluated against client-approved limits to ensure size consistency and fit accuracy.

E. Label & Logo

Apparel orders often include multiple colors and sizes, each requiring corresponding labels. This includes size labels, barcodes, hang tags, and care labels. During inspection, each label type is verified for accuracy and documented with photographs. This helps prevent labeling errors, customs risks, and market compliance issues.

F. Packing & Packaging

According to the client’s specifications, inspectors verify shipping marks, carton quality, packing methods, inner packaging printing, PVC bag integrity, desiccant placement, and overall packaging condition. This ensures product protection during transportation and compliance with logistics and warehouse requirements.

G. Common On-Site Tests for Garment Inspection

- Carton Assortment Check

- Needle Detection & Seam Strength Test

- Symmetry Check

- Color Shading Check

- Adhesive Tape Test

- Stretch Test (for elastic and knitted fabrics)

- Fatigue Test for Velcro, Snap, Zipper, and Eyelet

- Adhesion Test

- Color Rubbing Test

- Stitches Per Inch Check

- Barcode Scanning Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.