Houseware Quality Control

Global Quality, Local Expertise — NBNQC, Your Trusted Third-Party Inspection Authority. We support home goods brands worldwide with professional supply chain quality control and inspection services in China.

Houseware Quality Inspection Services

We specialize in providing comprehensive houseware quality control services, helping ensure that every home goods product meets high standards of quality, safety, and regulatory compliance. From detailed inspections of kitchenware and tableware to functional testing of bathroom and sanitary products, our experienced inspectors safeguard product integrity and brand reputation throughout the global supply chain.

Key Inspection Points for Houseware Products

Houseware inspection involves systematic evaluation of physical appearance, material quality, workmanship, functional performance, and dimensional accuracy for products such as kitchenware, tableware, and sanitaryware. Inspections also verify compliance with safety regulations, chemical substance requirements, labeling accuracy, and packaging integrity to ensure products are safe, durable, and user-friendly.

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packaging

- On-Site Tests

A. Appearance & style

Inspectors compare finished products against approved reference samples or product specifications to ensure consistency in style, structure, color, surface finish, and decorative details. Any deviation from the approved standard is documented and reported for corrective action.

Visual inspection also checks for surface defects such as scratches, dents, stains, uneven coating, deformation, and color inconsistency that may affect product appearance or perceived quality.

(Image example: Candles, Tableware, Glass Cup and Sauce )

B. Material

Inspectors begin by reviewing product specifications to confirm the required material types and grades. The actual products are then physically examined to verify material compliance through tactile assessment (texture, weight), visual inspection (surface quality, finish), and odor checks to detect potential chemical contamination or substandard materials.

When necessary, advanced laboratory testing methods such as chemical analysis or spectrometry are applied to verify material composition and detect restricted substances, including heavy metals (e.g., lead in ceramics) or harmful chemicals (e.g., BPA in plastics). This ensures product safety and regulatory compliance for international markets.

C. Workmanship

C1. Sampling

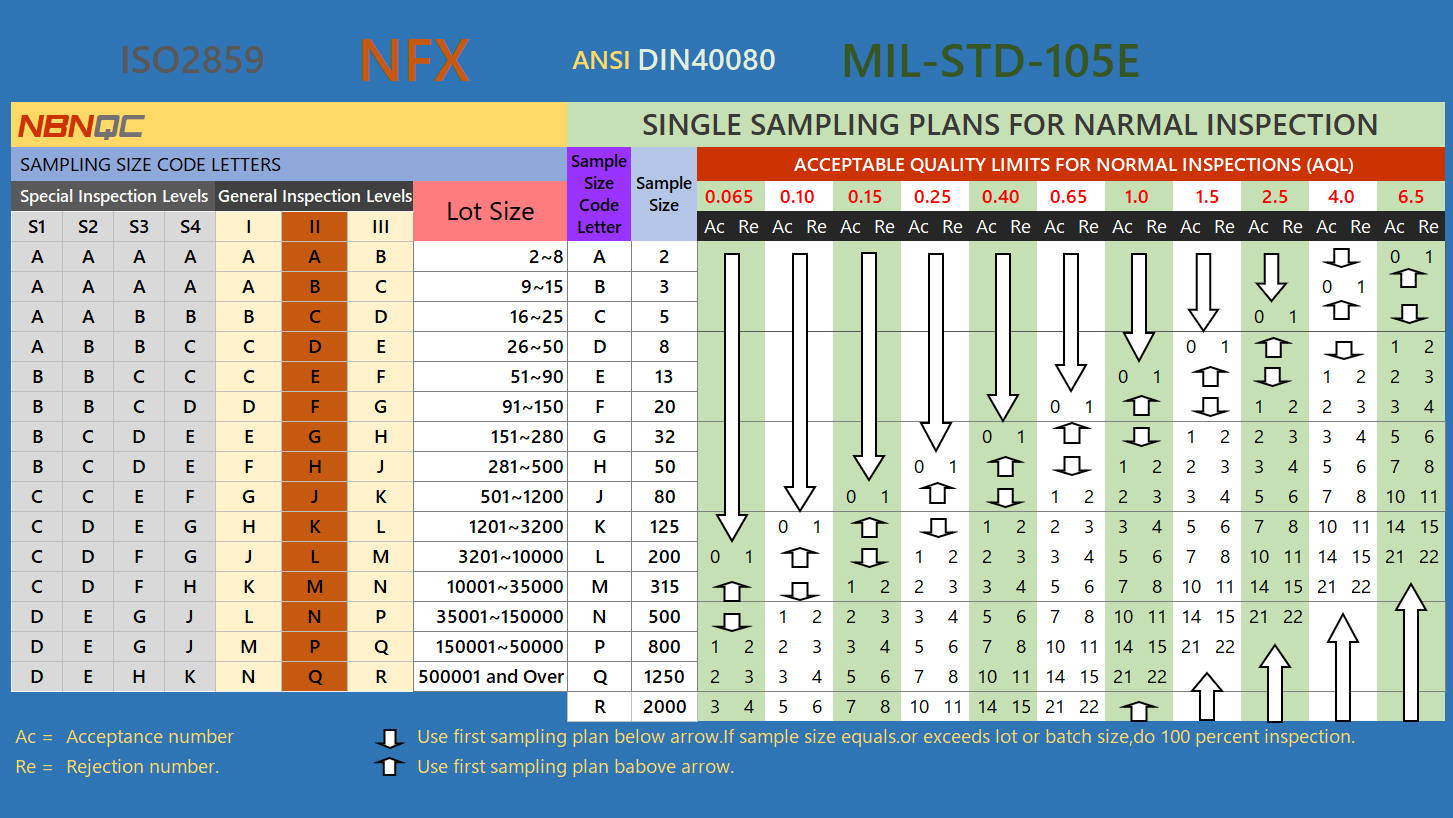

The quantity of inspection samples is determined based on the requested inspection level and total lot size, in accordance with internationally recognized AQL (Acceptance Quality Limit) standards. For example, under Inspection Level II with an AQL of 0 / 2.5 / 4.0 and a lot size of 5,000 pieces, 200 units will be randomly selected for inspection.

Acceptance criteria define the maximum allowable number of defects (Critical: 0 pcs / Major: 10 pcs / Minor: 14 pcs). If defect quantities exceed these limits, the shipment is classified as failed.

(Default standard: Inspection Level II, AQL 0 / 2.5 / 4.0.)

C2. Quality check

Each selected sample is individually examined to identify workmanship defects, functional issues, cosmetic imperfections, and assembly inconsistencies. All defective items are segregated, classified, photographed, and recorded.

Defect quantities are statistically evaluated against AQL acceptance limits to determine whether the production lot meets shipment approval requirements. This provides an objective basis for shipment release, conditional acceptance, corrective actions, or rejection decisions.

C3. Classification of Defects for Houseware Products

D. Size Measurement

Inspectors use calibrated tools such as rulers, calipers, measuring tapes, and digital measuring devices to verify product dimensions including length, width, height, thickness, and critical functional areas. Measurements are compared against approved specifications, drawings, or applicable standards to ensure dimensional accuracy and consistency.

This process ensures proper product fit, usability, packaging compatibility, and manufacturing stability.

E. Label & Logo

Inspectors verify the correct placement, size, color, design, and legibility of labels and logos against approved artwork or samples. All printed information — including product name, brand identity, compliance markings, usage instructions, and warning labels — is checked for accuracy and regulatory compliance.

Label application quality is also evaluated to ensure secure attachment, resistance to peeling, fading, or smudging, which is essential for maintaining brand integrity and traceability.

F. Packing & Packaging

Inspectors evaluate the strength, durability, and suitability of packaging materials to ensure adequate protection during transportation and storage. This includes checking carton strength, cushioning materials, internal fixation, moisture resistance, and packaging integrity.

Packaging information such as shipping marks, barcodes, product descriptions, and handling instructions is verified for accuracy and completeness. For products requiring assembly, inspectors also confirm that all components and accessories are correctly packed and securely protected.

G. Common On-Site Tests for Houseware Inspection

- Carton Assortment Check

- Waterproof Test

- Flame Retardant Test

- Odor (Smell) Test

- Color Shading Check

- Functional Test

- Pull Strength Test

- Fatigue Test

- Adhesion Test

- Rub Test

- Carton Drop Test

- Barcode Scan Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.