Jewelry Products Quality Control

Quality Begins in the Details.

NBNQC provides professional jewelry quality control and inspection services in China, ensuring compliance with international standards while protecting product quality and brand reputation.

Jewelry Quality Inspection Services

We specialize in delivering comprehensive jewelry inspection services, covering precious metals, gemstones, fashion jewelry, and customized pieces. Our inspection programs are tailored to product type, order requirements, destination-market regulations, and brand quality standards.

Our services help you:

- Verify material authenticity and compliance

- Ensure precision craftsmanship and consistent finishing

- Detect hidden defects and functional risks

- Confirm labeling accuracy and packaging integrity

- Reduce shipment risk and after-sales issues

Key Inspection Points for Jewelry Products

Jewelry inspection focuses on verifying material authenticity, manufacturing quality, aesthetic consistency, functional performance, and compliance with brand standards. Typical inspection scope includes:

- Authenticity & Quality of Materials

- Craftsmanship & Manufacturing Quality

- Design & Appearance Consistency

- Labeling & Packaging Verification

- Functional & Performance Testing

A. Authenticity & Quality of Materials

Inspectors verify the authenticity, purity, and quality of metals, gemstones, and decorative materials using appropriate physical and chemical testing methods.

Key inspection activities include:

B. Craftsmanship & Manufacturing Quality

Our inspectors evaluate overall workmanship to ensure products meet approved samples, technical specifications, and brand quality benchmarks. The inspection focuses on appearance consistency, structural reliability, and long-term durability.

Key inspection areas include:

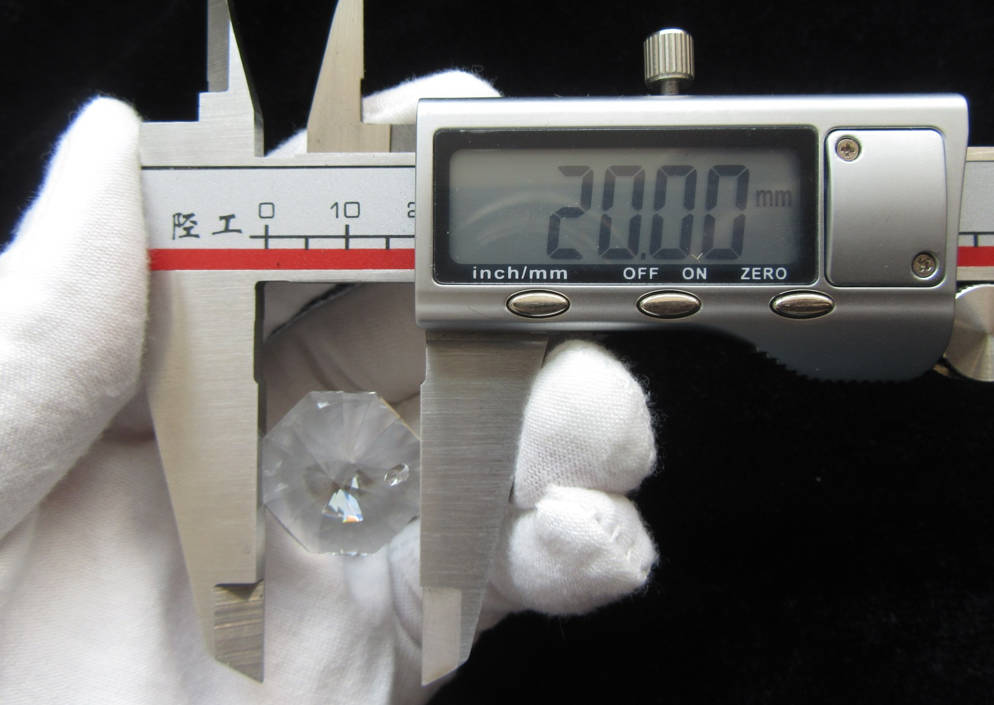

C. Design & Appearance Consistency

Inspectors verify that each jewelry item accurately reflects the approved design and customer specifications.

Inspection scope includes:

- Color accuracy and gemstone consistency

- Pattern alignment and symmetry

- Dimensional accuracy and weight tolerance

- Surface finish, plating quality, and polishing level

- Overall style conformity to approved samples

Any visual deviation, inconsistency, or aesthetic defect is clearly documented.

D. Labeling & Packaging Verification

Correct labeling and premium packaging are essential for brand image, compliance, and customer confidence.

Inspection covers:

- Accuracy of product labels, tags, barcodes, and markings

- Certification labels and origin information compliance

- Packaging material quality and protective performance

- Inner and outer packaging consistency with brand standards

- Carton markings, shipping labels, and packing integrity

Common On-Site Tests for Jewelry Inspection

- Functionality Test

- Capacity / Load Test

- Tensile Strength Test

- Torque Test (Twist Resistance)

- Fatigue / Repeated Use Test

- Odor / Smell Test

- Color Fastness Test

- Rub / Abrasion Test

- Wash Resistance Test

- Drop / Impact Test

- Barcode Scanning Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.