Makeup Tools Quality Control

NBNQC delivers professional quality control and inspection services for makeup tools manufactured in China, ensuring compliance with international standards and safeguarding product quality, brand reputation, and consumer trust.

Makeup Tools Quality Inspection Services

We provide comprehensive makeup tools quality control services, supporting global brands, importers, and retailers with reliable on-site inspections and factory quality monitoring. Our inspection programs cover the entire production cycle — from raw material verification and in-process quality control to final random inspection and shipment release.

Every brush, sponge, and applicator is evaluated for material safety, functional reliability, structural durability, and cosmetic consistency, helping clients reduce quality risk, improve batch stability, and maintain regulatory compliance.

Key Inspection Scope for Makeup Tools

Makeup tools inspection focuses on ensuring product safety, functional performance, manufacturing consistency, and regulatory compliance. Typical inspection scope includes:

- Appearance & Style

- Material Safety & Performance

- Workmanship (AQL Sampling)

- Dimensions & Weight

- Label & Logo

- Packing & Packaging

- On-Site Functional & Safety Tests

A. Appearance & Style

Inspectors compare finished products against approved samples or design specifications to verify consistency in appearance, structure, and color. Key evaluation areas include brush head shape, trimming uniformity, handle structure, surface finish, coating quality, decorative elements, and branding clarity. Color consistency is verified using Pantone color charts or approved reference samples.

Visual inspection also evaluates surface defects, coating uniformity, deformation, contamination, and assembly appearance to ensure products meet aesthetic expectations and brand presentation standards.

B. Material Safety & Performance

Material inspection evaluates the safety, suitability, and durability of all components used in makeup tools. Inspectors verify bristle type and density, handle materials, coating integrity, sponge elasticity and porosity, adhesive bonding strength, and overall material stability.

Where applicable, material safety compliance is verified against restricted substance requirements and industry safety regulations to ensure that materials meet client specifications and destination-market compliance standards.

C. Workmanship (AQL Sampling)

C1. Sampling Plan

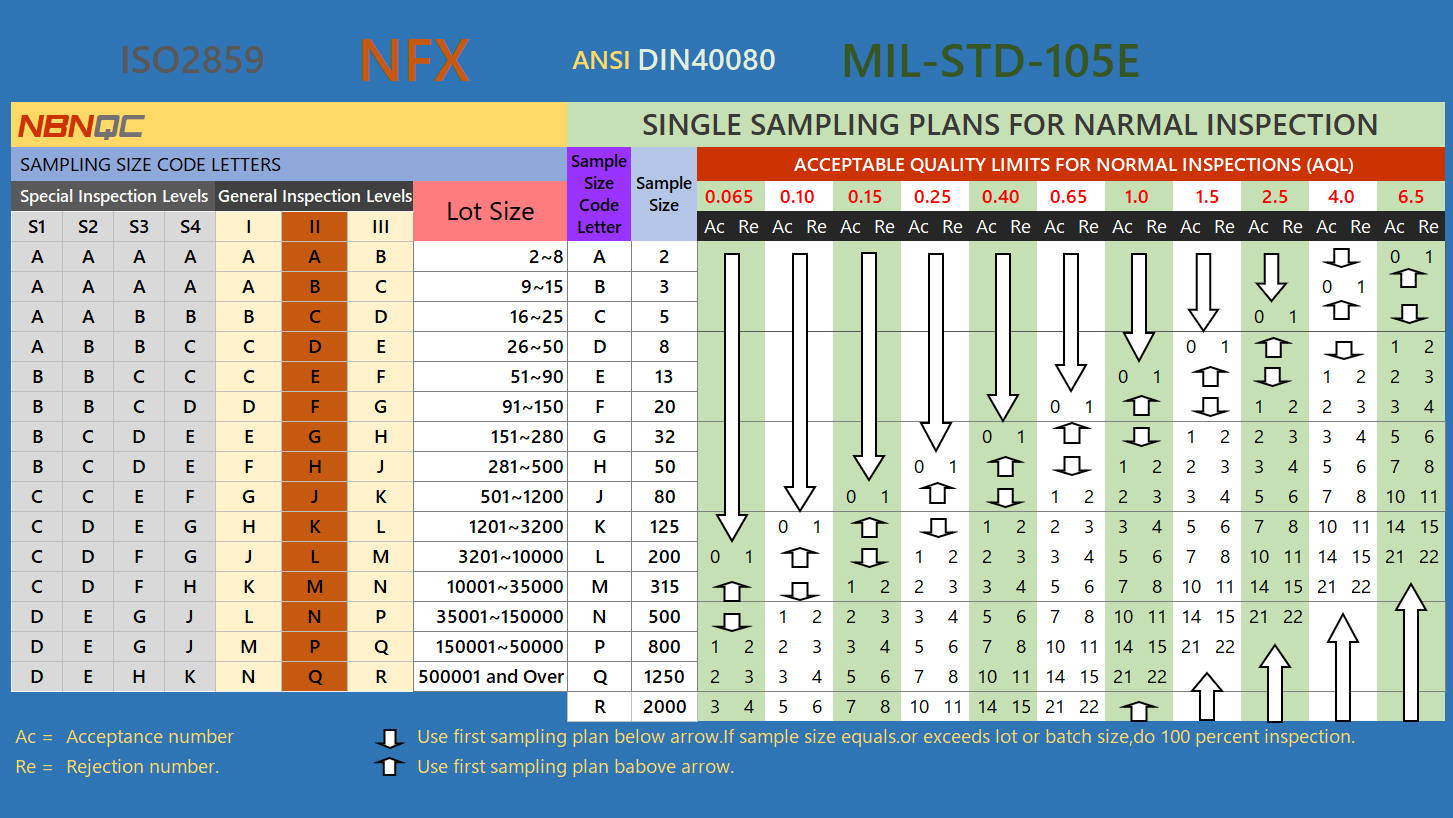

Random sampling quantity is determined based on the required inspection level and lot size according to AQL standards. For example, under Inspection Level II with an AQL of 0 / 2.5 / 4.0 and a lot size of 5,000 units, 200 pieces are randomly selected.

Acceptance limits are typically defined as Critical: 0 pcs, Major: 10 pcs, and Minor: 14 pcs. If the number of detected defects exceeds these limits, the shipment may be rejected or subject to corrective action.

(Default setting: Inspection Level II, AQL 0 / 2.5 / 4.0)

C2. Quality Evaluation & Decision Rule

Each sampled unit is individually examined against approved samples, product specifications, and workmanship standards. All detected defects are identified, classified, quantified, and documented with photographic evidence.

The final inspection result determines whether the shipment meets acceptable quality limits and whether it is approved for shipment, requires rework, or is rejected. Clear defect statistics and visual evidence enable buyers to make fast and informed shipment decisions.

C3. Defect Classification for Makeup Tools

D. Dimensions & Weight

Inspectors verify that product dimensions and weight comply with approved specifications and tolerance requirements. Key measurements may include overall length, handle diameter, brush head size, sponge thickness, and critical functional dimensions affecting usability and ergonomics.

Weight verification ensures product consistency, balance, and packaging accuracy. Excessive deviation may indicate material inconsistency, internal defects, or incorrect assembly. Measurements are conducted using calibrated measuring tools and digital scales, with results recorded for traceability and batch consistency evaluation.

E. Label & Logo

Label and logo verification ensures that all markings comply with approved artwork, regulatory requirements, and client branding standards. Inspectors verify logo placement, size, clarity, printing accuracy, durability, and resistance to abrasion or fading.

Product labels are checked for correct product identification, manufacturing information, batch traceability, country of origin, and required compliance symbols to ensure accurate market labeling and regulatory conformity.

F. Packing & Packaging

Packaging inspection evaluates whether products are adequately protected during handling, storage, and transportation while maintaining compliance and presentation quality. Inspectors verify carton strength, internal protection materials, stacking stability, barcode accuracy, printing quality, labeling accuracy, and warning marks.

All packaging must conform to approved packaging specifications and applicable regulatory requirements.

G. Common On-Site Tests for Makeup Tools Inspection

- Carton Assortment Check

- Odor (Smell) Test

- Durability and Stress Test

- Functional Test

- Color Fastness Test

- Adhesion Test

- Barcode Scanning Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.