Mechanical Parts Quality Control

NBNQC provides precise and reliable mechanical parts inspection services across China & Asia, ensuring critical components meet strict technical and regulatory requirements to protect product quality and safety.

Mechanical Parts Quality Control & Inspection Services

NBNQC provides professional mechanical parts quality control services, supporting global buyers with on-site inspections across major manufacturing regions. Our inspection programs focus on verifying dimensional accuracy, material conformity, surface quality, and overall structural integrity to ensure full compliance with approved drawings and technical specifications.

Serving industries such as industrial machinery, medical devices, and precision engineering, we deliver dependable quality assurance for both mass production and customized components, helping clients effectively reduce quality risks before shipment.

Key Inspection Points for Mechanical Parts

The primary objective of mechanical parts inspection is to confirm that all products comply with design drawings and technical specifications. Inspections focus on dimensional accuracy, material properties, surface condition, and functional integrity.

In addition, inspectors check for visible defects such as deformation, cracks, corrosion, or rust, which could affect performance, safety, or long-term durability.

Typical inspection scope includes:

- Material Check

- Visual Inspection

- Dimensional Measurement

- Packing & Packaging

- On-site Tests

A. Material Check

Based on the material specifications defined in the client’s drawings or technical documents, inspectors conduct preliminary material verification using appropriate testing instruments such as hardness testers and spectrometers.

To further ensure material compliance, inspectors also review supporting documents provided by the supplier, such as raw material certificates and mill test reports, including:

- Raw material purchase records

- Mill test certificates (MTC)

- Material test reports from certified suppliers

This process helps confirm that the actual materials used in production fully match the required material grades and mechanical properties.

B. Visual Inspection

Visual inspection focuses on identifying surface defects, machining quality issues, and obvious damage that could affect functionality or appearance.

Inspectors examine:

- Surface finish and coating quality

- Burrs, sharp edges, scratches, dents, or cracks

- Signs of corrosion, oxidation, or contamination

- Assembly quality (if applicable)

Visual checks help identify workmanship issues that may not appear in dimensional or functional testing but can still affect product reliability.

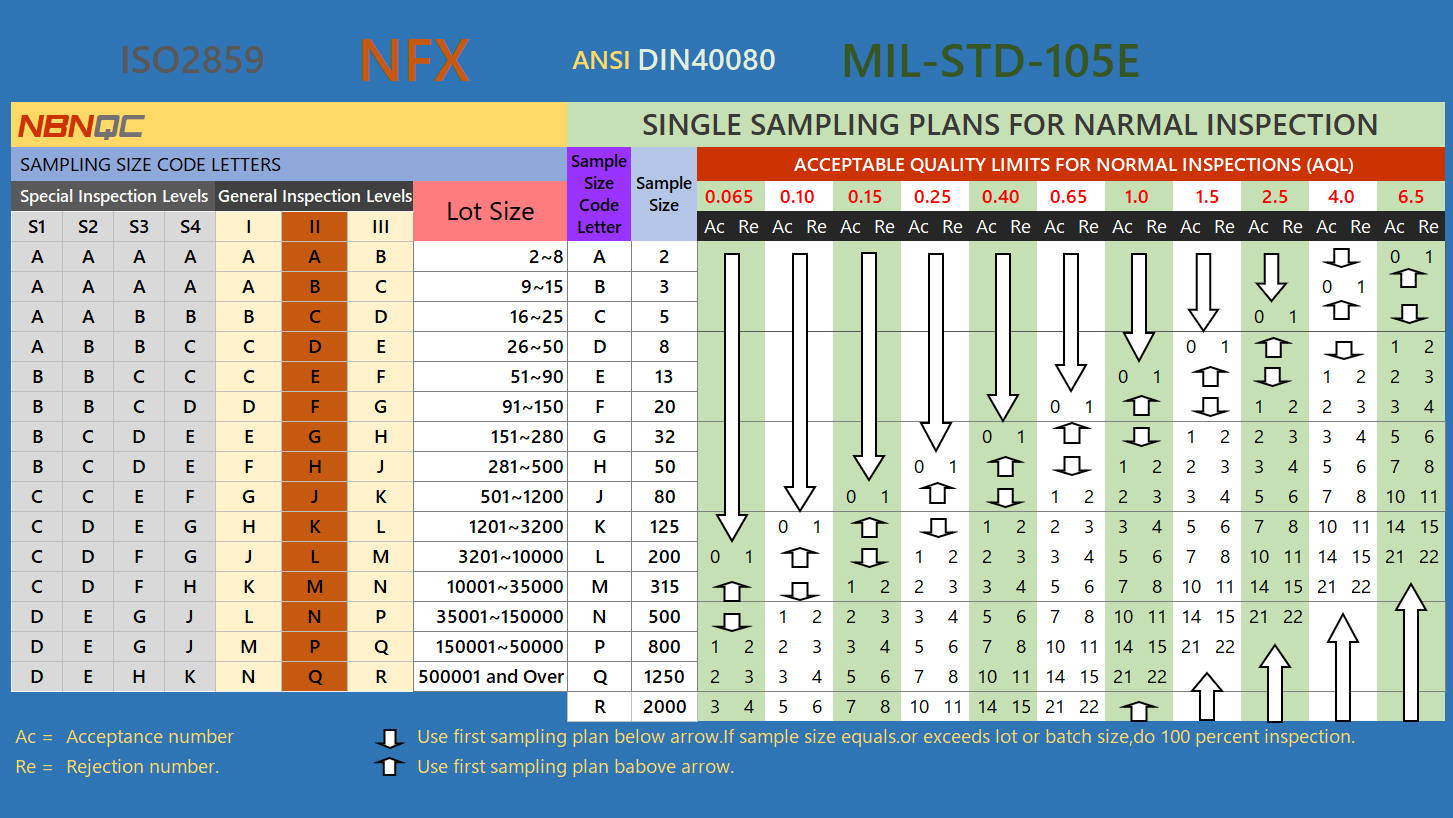

B1. Sampling (AQL Inspection)

Sampling inspection is conducted based on the inspection level requested by the client and the total lot size, in accordance with internationally recognized AQL (Acceptance Quality Limit) sampling standards. This method ensures that a statistically representative number of units is selected to evaluate overall batch quality.

Under default settings (Inspection Level II, AQL 0 / 2.5 / 4.0), inspectors randomly select samples from the shipment and assess defect quantities against acceptance criteria. If defect levels exceed the allowable limits, the shipment will be rejected, helping clients effectively control shipment risk before delivery.

B2. Quality Check (Defect Sorting & Evaluation)

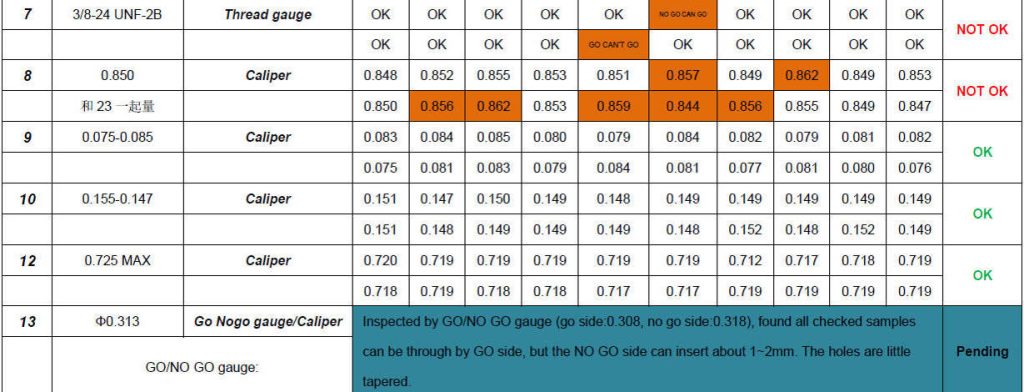

Each selected sample is inspected individually according to product specifications and inspection requirements. Inspectors carefully examine workmanship, appearance, dimensions, and functional aspects to identify any non-conformities.

All detected defects are recorded and classified by severity, and the final defect statistics are compared with the applicable AQL acceptance limits. This evaluation determines whether the entire shipment is approved for release or requires corrective action before shipment.

B3. Classification of Defects in Mechanical Parts

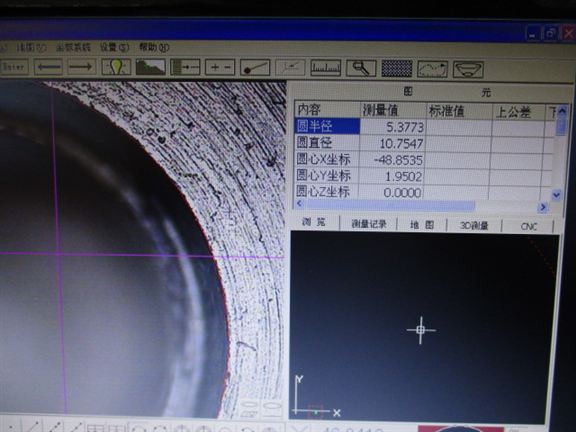

C. Dimensional Measurement

Dimensional verification is conducted using appropriate precision instruments such as calipers, micrometers, and CMM equipment, selected according to part complexity and tolerance requirements.

Inspectors measure key dimensions at multiple points and compare all results with engineering drawings and tolerance limits to confirm full compliance with design specifications.

D. Packing & Packaging

Proper packaging is essential to protect mechanical parts during storage and transportation.

Inspectors verify that packaging materials provide adequate protection, that anti-rust measures are applied when necessary, and that parts are securely positioned to prevent damage in transit. Packaging labels are also checked to ensure correct identification and handling.

E. Common On-Site Tests for Mechanical Parts

- Material composition analysis

- Surface finish examination

- Structural integrity testing

- Hardness testing

- Functional performance testing

- Salt spray corrosion testing

- Load and stress testing

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.