Promotional Products Quality Control

Strengthening Global Brands with Local Expertise — Providing Comprehensive Quality Control Services for Promotional Products in China. Elevating Standards, Ensuring Satisfaction.

Promotional Products Quality Inspection Services

With a strong focus on detail and quality consistency, we ensure that every promotional item meets defined standards for functionality, appearance, and brand presentation — accurately representing your brand in the marketplace.

In markets where first impressions influence purchasing decisions, our inspection services help protect product integrity and visual consistency. Through systematic on-site inspections and verification against international standards and buyer specifications, we support stable product quality and reliable brand performance across each shipment.

Key Inspection Points for Promotional Products

Promotional products inspection includes thorough evaluations of material quality, construction and workmanship, size and dimensional accuracy, design and color consistency, labeling and packaging accuracy, safety compliance, and overall appearance and finish.

Our inspection services focus on verifying product appearance, durability, logo consistency, and regulatory compliance — ensuring that each item not only meets aesthetic expectations but also delivers reliable performance and safety for end users.

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packing & Packaging

- On-Site Tests

A. Appearance & Style

The inspection process includes a comprehensive evaluation of the product’s appearance to confirm alignment with order requirements and client specifications. Inspectors verify color accuracy, design alignment, logo positioning, surface finish, and overall aesthetic consistency to ensure the product matches approved samples and brand guidelines.

Products are carefully compared against reference samples or technical specifications, with close attention paid to textures, finishes, printing quality, and critical design elements that directly impact brand image and market acceptance.

B. Material

Inspectors verify that all materials used in the product comply with the specifications defined in the purchase order or technical documentation. For products requiring special material properties — such as water resistance, flame retardancy, or abrasion resistance — appropriate functional or laboratory tests are conducted when required.

Material verification also includes confirming compliance with relevant safety and environmental regulations, such as REACH, RoHS, or destination-market chemical requirements. Any presence of restricted substances or non-compliant materials is recorded and reported.

C. Workmanship

C1. Sampling

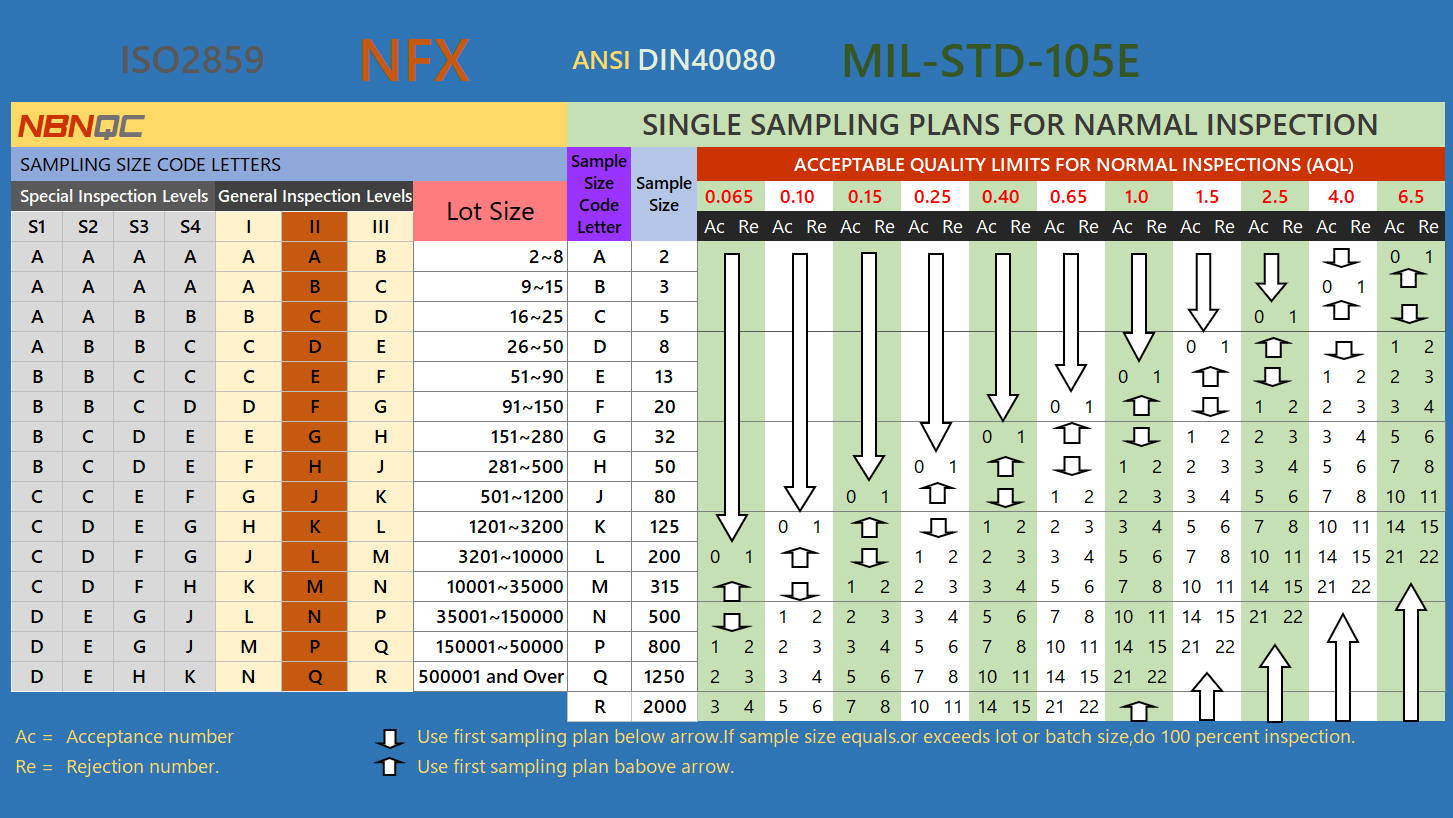

The number of samples for random inspection is determined based on the inspection level requested by the client and the lot size of the shipment, in accordance with the AQL sampling standard.

For example, if the required inspection level is II, the AQL is 0 / 2.5 / 4.0, and the lot size is 5,000 pieces, then 200 pieces will be randomly selected for inspection. The acceptance limits would be:

- Critical defects: 0 pcs

- Major defects: 10 pcs

- Minor defects: 14 pcs

If the number of defects exceeds these limits, the shipment will be rejected.

(Default: Inspection Level II, AQL 0 / 2.5 / 4.0)

C2. Quality Check

Each selected sample is individually examined. All detected defects are identified, classified, and recorded. Defective products are segregated and counted by defect category.

The inspection results determine whether the entire shipment falls within the acceptable AQL range and serve as the primary basis for shipment acceptance or rejection.

C3. Classification of Defects in Promotional Products

D. Size Measurement

Key dimensions — including length, width, height, diameter, and thickness — are measured according to the product specifications. Product-specific features such as logo size, print area dimensions, and attachment positioning are also verified when applicable.

Measured results are compared against approved samples or technical drawings. Any deviation exceeding the allowed tolerance is recorded as a dimensional defect.

E. Label & Logo

Inspectors verify label and logo accuracy in terms of color, size, placement, font, and content against approved artwork and reference samples. Printing clarity, adhesion strength, embroidery quality, and abrasion resistance are evaluated when applicable.

All required labeling information — including material composition, care instructions, barcode accuracy, country of origin, and compliance symbols — must be present, legible, and correctly applied. Photographic records are taken to document inspection findings.

F. Packing & Packaging

Packaging inspection includes verification of carton strength, thickness, sealing integrity, internal protection materials, and packing method to ensure products are protected during transportation and handling.

Inspectors also confirm that packaging complies with branding and shipping requirements, including shipping marks, carton labeling accuracy, logo usage, color consistency, and required handling instructions.

G. Common On-Site Tests for Promotional Products Inspection

- Carton Assortment Check

- Needle Detection & Seam Strength Test

- Symmetry Check

- Color Shading Check

- Sticker Test

- Stretch Test (for Elastic and Knitted Fabrics)

- Fatigue Test

- Adhesive Test

- Rub Test

- Per Inch Stitches Check

- Barcode Scanning Test

- Carton Drop Test

- Flame Retardant Test

- Waterproof Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.