Specialized Equipment Quality Control

Ensuring Excellence in Specialized Equipment — Your Trusted Partner in Asia for Comprehensive Quality Inspection Services.

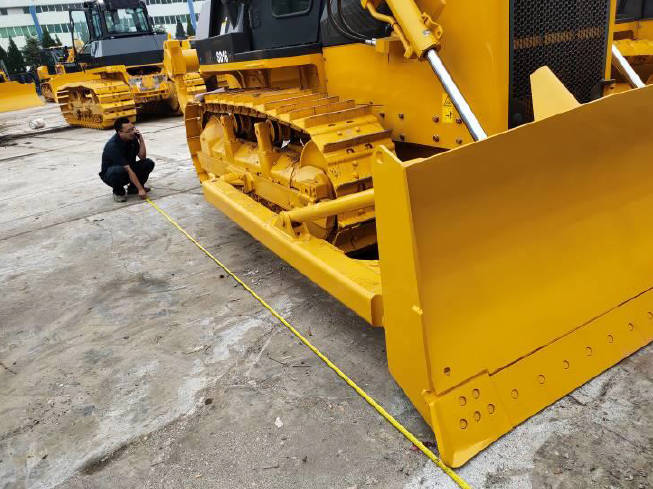

Specialized Equipment Quality Inspection Services

With a strong focus on precision, reliability, and regulatory compliance, we ensure that all specialized equipment meets strict quality and performance standards before shipment or installation. Our experienced inspectors apply standardized inspection procedures, calibrated measuring instruments, and appropriate testing methods to conduct thorough inspections and objective evaluations.

Whether the equipment is used in construction, manufacturing, medical, power, transportation, or other specialized industries, our inspection services are designed to reduce technical risks, prevent costly failures, and provide buyers with confidence in product quality and operational safety.

Key Inspection Points for Specialized Equipment

Specialized equipment inspection is a systematic quality control process involving detailed verification of functional performance, safety compliance, structural integrity, calibration accuracy, and supporting documentation. This comprehensive approach ensures that the equipment operates efficiently, safely, and in accordance with applicable industry standards and client requirements.

Through structured inspection procedures and clearly defined acceptance criteria, we help clients confirm that equipment is suitable for its intended application and compliant with destination-market regulations.

Typical inspection scope includes:

- Function tests

- Safety and Compliance Checks

- Physical and Structural Integrity Assessment

- Precision and Calibration Verification

- Documentation Review

- Customized Inspection Criteria

A. Function tests

A1. Operational Test

The equipment is activated and operated through its full functional range to verify that all features perform correctly and consistently. Inspectors evaluate system response, operational stability, and control accuracy under normal working conditions.

For example, in medical equipment, this may include checking imaging clarity, signal accuracy, and system responsiveness. In manufacturing machinery, it typically involves verifying operational speed, motion accuracy, and automation performance.

A2. Load and Stress Test

Where applicable, the equipment is tested under rated load or simulated maximum operating conditions to confirm that it can function safely and reliably under real working stress.

For construction equipment, this may involve lifting or moving maximum weight loads. For electrical or electronic equipment, it may include long-duration operation or testing under varying power conditions. This process helps identify potential failures that may not be detected under light-load or short-duration testing.

B. Safety and Compliance Checks

B1. Safety Standards Assessment

The equipment is examined against relevant local and international safety standards. Inspectors verify the presence and correct functioning of safety features such as emergency stop buttons, protective guards, interlock systems, and warning devices.

In heavy machinery, attention is given to mechanical protection systems and emergency shutdown functions. In electrical equipment, insulation condition, grounding systems, and wiring safety are carefully checked to prevent electrical hazards.

B2. Regulatory Compliance Verification

The equipment is reviewed for compliance with industry-specific regulations and certifications, such as CE marking, UL certification, or other required approvals depending on destination market regulations.

Inspectors verify that nameplates, labels, and certificates are accurate and complete. Environmental compliance items, including emissions limits and hazardous substance restrictions, may also be reviewed when required by the destination market or client specifications.

C. Physical and Structural Integrity Assessment

C1. Visual Inspection

A detailed visual examination is performed on both external and accessible internal components. Inspectors look for signs of:

- Corrosion or material deterioration

- Cracks or deformation

- Poor welding quality

- Loose or missing fasteners

- Excessive wear on moving parts

High-stress and load-bearing areas receive special attention to detect early signs of fatigue or structural failure.

C2. Non-Destructive Testing (NDT)

When required, advanced non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, or radiographic (X-ray) testing are applied to detect internal defects without damaging the equipment.

These methods are particularly important for pressure vessels, welded structures, pipelines, and safety-critical components, where internal flaws could lead to serious operational risks.

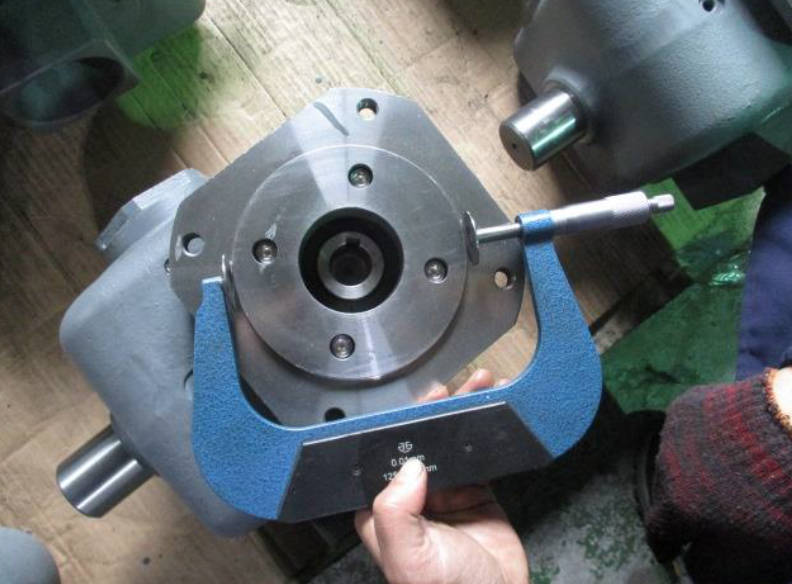

D. Precision and Calibration Verification

D1. Calibration Check

The equipment is tested against traceable reference standards using calibrated measuring instruments to verify that outputs and readings fall within specified tolerance limits.

For example, laboratory equipment may be calibrated using certified reference materials, while CNC machines and precision tools are checked for dimensional accuracy and alignment to ensure stable production quality.

D2. Repeatability and Consistency Test

The equipment is operated repeatedly under the same conditions to confirm stable and repeatable performance. This test verifies that the equipment delivers consistent results over continuous use, which is essential for automated production systems and medical diagnostic equipment.

D3. Software and Firmware Verification

For digitally controlled equipment, inspectors verify software and firmware versions, system stability, and interface functionality. Basic control logic is tested to ensure that digital commands are accurately translated into mechanical or electrical actions.

E. Documentation Review

Inspectors review all relevant technical and compliance documents, including:

- Safety and conformity certificates (CE, ISO, industry approvals, etc.)

- Calibration and test records

- Operation and maintenance manuals

- Factory quality records and inspection reports

This step confirms that documentation is complete, accurate, and consistent with the actual configuration of the equipment.

F. Client Specifications and Project Requirements

Specialized equipment covers a wide range of industries, each with unique operating conditions and performance expectations. Therefore, client-defined technical specifications and project requirements are critical parts of the inspection process.

Inspectors carefully review all drawings, performance parameters, contractual quality standards, and regulatory requirements provided by the client. Each requirement is verified point by point during inspection to ensure that the equipment fully meets both quality expectations and safety obligations for its intended application.

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.