Stationery Quality Control

Precision in Every Pencil, Integrity in Every Ink — Crafting Quality, Building Trust. As your professional stationery quality control partner, we ensure consistent quality in every product.

Stationery Quality Control & Inspection Services

We specialize in delivering professional stationery quality control services, ensuring that every stationery product — from pens and pencils to notebooks and organizers — meets defined standards of quality, safety, and performance. Our comprehensive approach includes detailed inspections and appropriate testing to verify that each product complies with industry requirements and customer specifications.

Through systematic quality control procedures, we help clients reduce quality risk, improve product consistency, and maintain reliable market performance in terms of functionality, durability, and appearance.

Key Inspection Points for Stationery Products

Stationery inspection includes evaluating physical and mechanical performance, verifying compliance with safety standards (such as non-toxic materials and child safety regulations), checking consistency in design and dimensions, confirming product functionality and durability, and assessing overall appearance and finishing quality.

This inspection process ensures that stationery products remain safe, reliable, and compliant with applicable regulatory and customer requirements.

Inspection Scope

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packing & Packaging

- On-Site Tests

A. Appearance & Style

Inspectors compare finished stationery products against approved samples or detailed product specifications provided by the client. Particular attention is paid to design accuracy, logo positioning, surface finish, and visual consistency to ensure compliance with brand requirements and aesthetic expectations.

Products are visually examined under standardized lighting conditions to verify color consistency and identify any discrepancies or fading. When specific color codes are provided, Pantone color charts are used for color verification and deviation recording.

B. Material

Inspectors review product specifications and material lists to confirm that all materials used in the product comply with approved requirements. This includes verifying paper types, plastics, metals, coatings, inks, and adhesive materials.

Material verification may involve visual inspection, tactile evaluation for texture and weight, odor checks for inks or adhesives, and document verification when necessary. Any material deviation or non-compliance is recorded and reported.

C. Workmanship

C1. Sampling

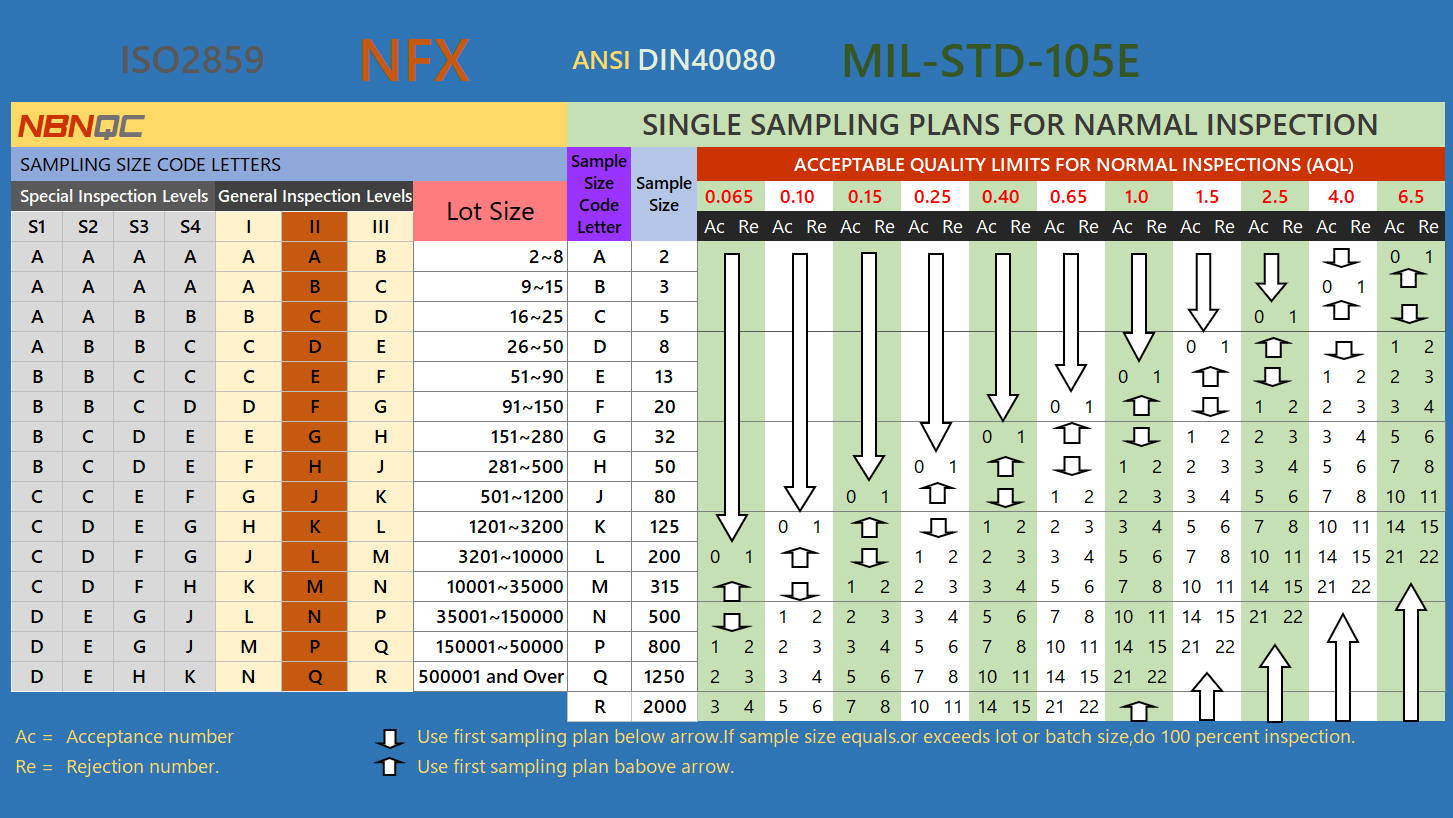

The number of samples selected for random inspection is determined based on the inspection level requested by the client and the lot size of the shipment, in accordance with the AQL sampling standard.

For example, if the required inspection level is II, the AQL is 0 / 2.5 / 4.0, and the lot size is 5,000 pieces, then 200 pieces will be randomly selected for inspection. The acceptance limits are:

- Critical defects: 0 pcs

- Major defects: 10 pcs

- Minor defects: 14 pcs

If the number of defects exceeds these limits, the shipment will be rejected.

(Default: Inspection Level II, AQL 0 / 2.5 / 4.0)

C2. Quality Check

Each selected sample is individually examined. All detected defects are identified, classified, and recorded. Defective products are segregated and quantified by defect category.

Inspection results determine whether the entire shipment falls within the acceptable AQL range and serve as the primary basis for shipment acceptance or rejection.

C3. Classification of Defects in Stationery

D. Size Measurement

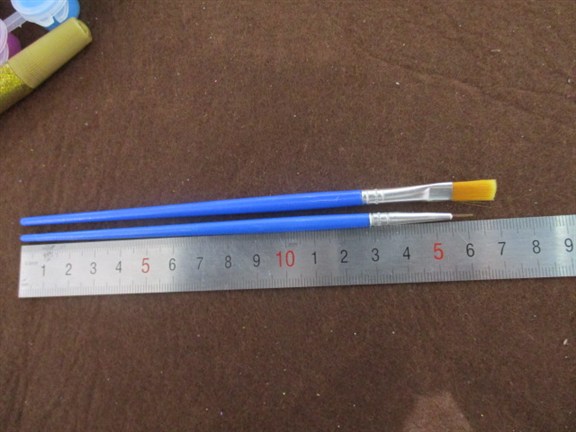

Inspectors measure key dimensions — including length, width, height, and thickness — according to client specifications or applicable standards.

For complex or irregular-shaped products, auxiliary measuring tools such as angle gauges or contour gauges may be used to ensure measurement accuracy. Measured results are compared against approved tolerances, and any deviation is recorded.

E. Label & Logo

Inspectors verify logo accuracy in terms of design, color, size, placement, and printing quality against approved artwork and specifications.

Labels are checked for correctness and legibility of required information, including product name, manufacturer information, production details, barcode accuracy, compliance markings, and safety warnings.

F. Packing & Packaging

Packaging inspection verifies the strength, thickness, sealing integrity, and protective performance of cartons, inner boxes, and cushioning materials to ensure products are adequately protected during transportation and storage.

Inspectors also confirm the accuracy of shipping marks, warning labels, inner packaging artwork, and the completeness of products, accessories, and instruction manuals.

G. Common On-Site Tests for Stationery Inspection

- Carton Assortment Check

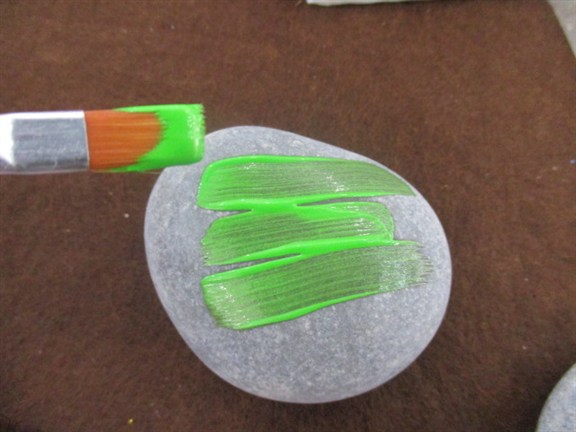

- Color Shading Check

- Sticker Adhesion Test

- Adhesive Strength Test

- Rub / Abrasion Test

- Function Test

- Waterproof Test

- Flame Retardant Test

- Odor (Smell) Test

- Fatigue Test

- Carton Drop Test

- Barcode Scanning Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.