Textiles & Fabrics Quality Control

Global Vision, Local Expertise – Your Trusted Textiles & Fabrics Inspection Partner in China. We are committed to delivering professional, accurate, and reliable textile quality control and inspection services for global clients.

Textiles & Fabrics Quality Inspection Services

As a professional textile inspection service provider, we deliver comprehensive textile quality control solutions. By working closely with our clients to understand their specific requirements, we develop and implement inspection processes aligned with international standards. Our professional inspection team conducts thorough on-site quality inspections at supplier facilities, covering raw materials, production processes, and finished products. After the inspection, we provide detailed reports with clear findings and improvement recommendations, ensuring that the textiles meet client quality requirements and applicable regulatory standards.

Key Inspection Points for Textiles & Fabrics

This includes comprehensive evaluation of raw material characteristics, fabric construction and workmanship, dimensional accuracy, color consistency, labeling and packaging compliance, on-site testing, and overall appearance and finishing quality.

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packaging

- On-Site Tests

A. Appearance & style

Samples or finished products are compared with the client’s approved samples or design specifications. This includes verifying fabric pattern, color, texture, and overall layout against the approved design. Inspectors carefully verify color accuracy and pattern details to identify any deviations. Fabric proportions and layout consistency are also confirmed. Inspections are conducted under sufficient natural or standardized lighting conditions to ensure accurate visual assessment.

B. Material

Inspectors evaluate fabric texture, thickness, and softness through tactile inspection to preliminarily assess material type and quality against specifications. This assessment relies on the inspector’s experience and professional judgment.

When required, a fabric sample of known size is weighed using a high-precision electronic scale to verify that the fabric grammage (GSM) meets order requirements. Inspectors may also request third-party fabric test reports from the supplier to verify fiber composition and chemical compliance.

C. Workmanship (Fabric Quality & Construction)

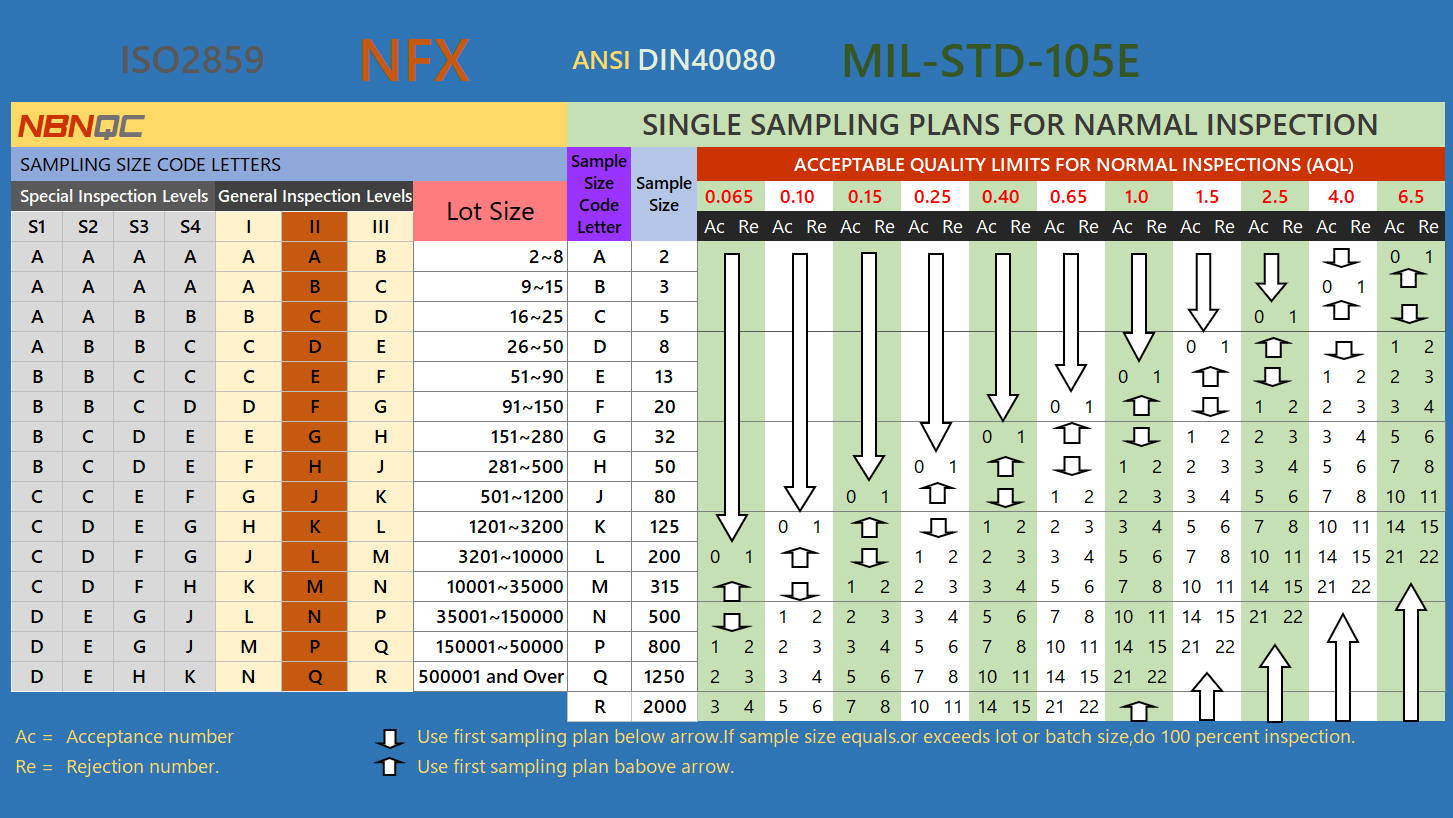

C1. Sampling

The number of fabric samples selected for inspection is determined based on the client’s inspection level and the total lot size. Samples are selected in accordance with the applicable AQL standard. For reference, when Inspection Level II and AQL 0 / 2.5 / 4.0 apply, the sample quantity and acceptance criteria are determined according to the AQL sampling table. If defect quantities exceed the acceptance limits, the lot will be rejected.

(Default: Inspection Level II, AQL 0 / 2.5 / 4.0)

C2. Quality check

Each selected fabric sample is individually examined for appearance, construction quality, and performance characteristics. Inspectors identify, record, and mark all defective areas. All defects are categorized and quantified according to severity levels. The final result determines whether the fabric lot complies with the specified AQL and forms the basis for shipment acceptance or rejection.

C3. Classification of Defects in Textiles & Fabrics

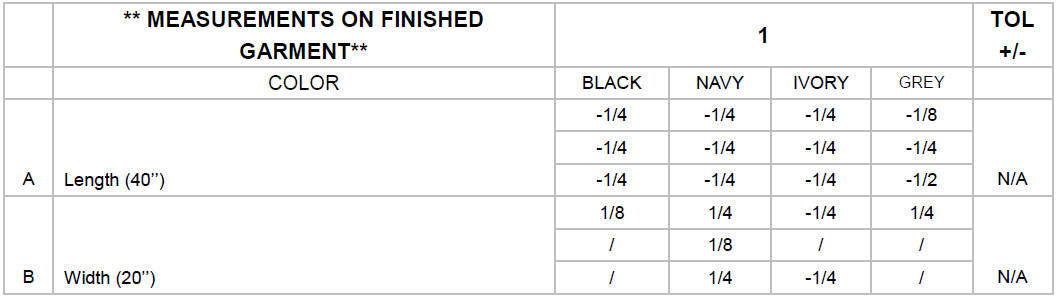

D. Size Measurement(Dimensional Verification)

Measurement specifications provided by the client may include fabric width, length, weight (GSM), roll size, and other dimensional requirements. Inspectors perform measurements based on the approved measurement chart and specified sample quantity. If any discrepancy is identified between client requirements and supplier specifications, inspectors promptly report and confirm the issue with the client before final evaluation.

E. Label & Logo (Fabric Identification & Marking)

For textile and fabric orders, labels and markings may vary depending on fabric type, batch, color, or roll specifications. These may include fabric identification labels, fiber content labels, batch numbers, barcodes, or brand logos applied to fabric rolls or packaging. During inspection, inspectors verify the accuracy, consistency, and placement of all labels and markings and document findings with clear photographic evidence. This helps prevent mislabeling risks and ensures traceability and regulatory compliance.

F. Packing & Packaging (Fabric Packing Inspection)

According to client packing specifications, inspectors verify packing methods (roll or folded), outer carton or bale condition, shipping marks, and labeling accuracy. Additional checks include inner packaging quality, moisture protection, plastic wrapping or PVC bag integrity, and desiccant placement when required, ensuring fabrics are properly protected during storage and transportation.

G. Common On-Site Tests for Textiles & Fabrics Inspection

- Carton Assortment Check

- Needle Detection & Seam Strength Test

- Symmetry Check

- Color Shading Check

- Adhesive Tape Test

- Stretch Test (for elastic and knitted fabrics)

- Fatigue Test for Velcro, Snap, Zipper, and Eyelet

- Adhesion Test

- Color Rubbing Test

- Stitches Per Inch Check

- Barcode Scanning Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.