Toys Quality Control

Ensuring Excellence in Toy Quality Control and Inspection Services — Safeguarding Your Global Supply Chain and Brand Compliance.

Toys Quality Control & Inspection Services

NBNQC is dedicated to upholding the highest standards of safety and craftsmanship in the toy industry. Our experienced inspection team conducts systematic evaluation and appropriate testing to ensure every product complies with global safety regulations and quality benchmarks.

By closely monitoring international regulatory requirements, we help brands and buyers reduce quality risks, improve product consistency, and protect consumer safety throughout the production and delivery process.

Key Inspection Points for Toys

Toy inspection focuses on comprehensive evaluation of product safety, quality consistency, and regulatory compliance. This includes verification of non-toxic materials, structural integrity, age appropriateness, and compliance with international and local safety standards.

Additional inspection scope includes functional testing to confirm proper operation, packaging verification for safety and labeling accuracy, and random sampling to ensure consistent quality across production batches.

Inspection Scope

- Appearance & Style

- Material

- Workmanship

- Size Measurement

- Label & Logo

- Packing & Packaging

- On-Site Tests

A. Appearance & Style

Inspectors cross-reference finished products against approved design documents, including technical drawings, color references, artwork files, and model specifications. Each toy is carefully evaluated to confirm that its shape, dimensions, color, surface finish, and functional features match approved requirements.

Particular attention is paid to visual consistency, molding accuracy, assembly quality, and decorative details to ensure products meet brand expectations and market acceptance standards.

B. Material

Material verification includes reviewing approved material specifications, conducting on-site verification, and performing laboratory testing when required to confirm material quality and safety compliance (such as EN71, ASTM F963, or destination market regulations).

Supply chain traceability, supplier documentation review, and cooperation with accredited laboratories help ensure that all materials used in toys meet applicable chemical safety, mechanical safety, and durability requirements.

C. Workmanship

C1. Sampling

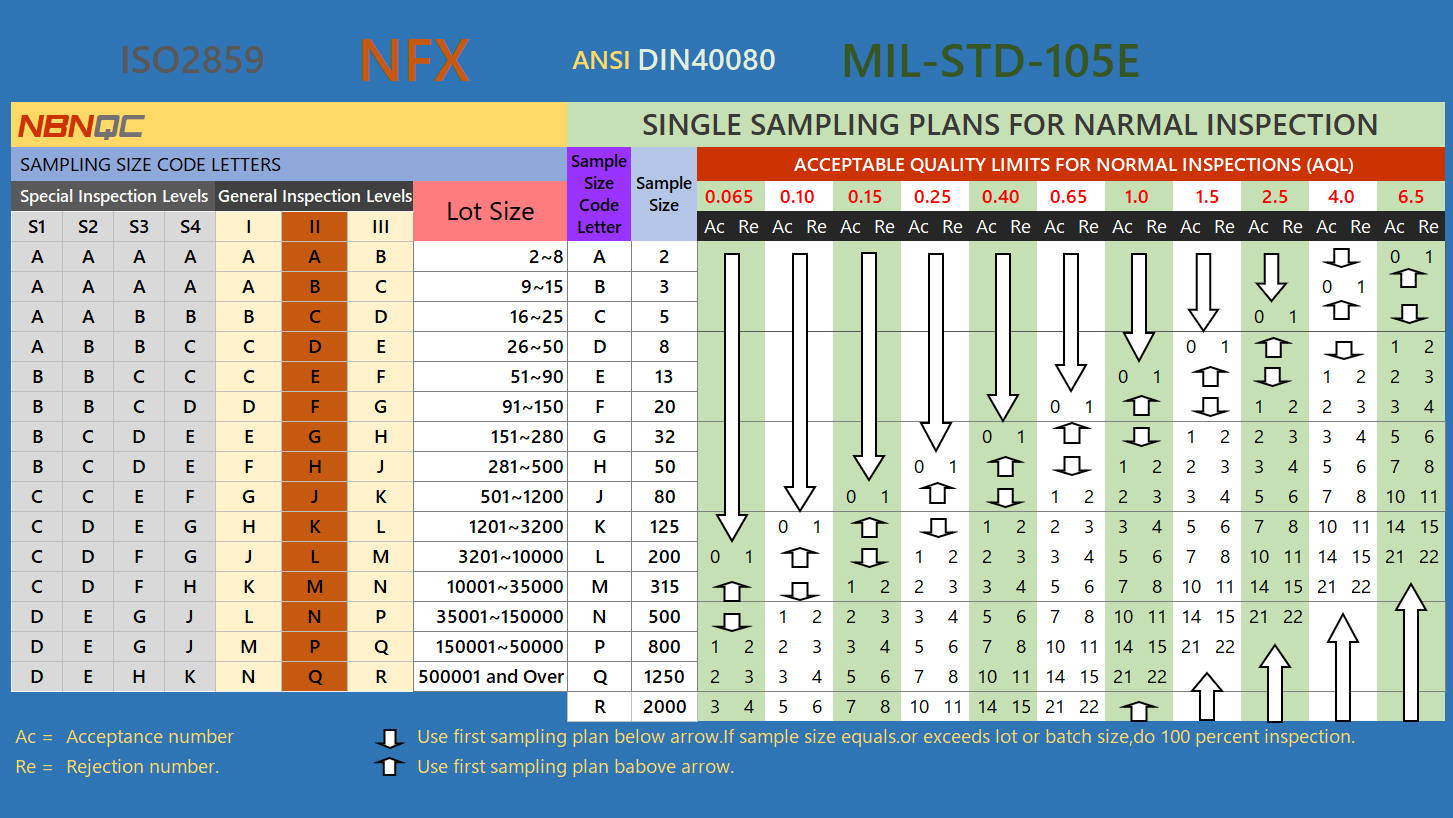

The number of samples selected for random inspection is determined based on the inspection level requested by the client and the lot size of the shipment, in accordance with AQL sampling standards.

For example, if the required inspection level is II, the AQL is 0 / 2.5 / 4.0, and the lot size is 5,000 pieces, then 200 pieces will be randomly selected for inspection. The acceptance limits are:

- Critical defects: 0 pcs

- Major defects: 10 pcs

- Minor defects: 14 pcs

If the number of defects exceeds these limits, the shipment will be rejected.

(Default: Inspection Level II, AQL 0 / 2.5 / 4.0)

C2. Quality Check

Each selected sample is individually examined. All detected defects are identified, classified, and recorded. Defective products are segregated and counted by defect category.

Inspection results determine whether the shipment falls within the acceptable AQL range and serve as the basis for shipment acceptance or rejection.

C3. Classification of Defects in Toys

D. Size Measurement

Inspectors measure key dimensions — including length, width, height, thickness, and other functional dimensions — according to approved specifications.

Multiple samples are measured to confirm dimensional consistency across the production batch. All results are recorded and compared against tolerance limits to verify compliance.

E. Label & Logo

Inspectors verify label and logo accuracy in terms of placement, size, color consistency, font style, and printing quality against approved artwork.

Mandatory labeling information — including safety warnings, age grading, manufacturer information, country of origin, and compliance marks — is checked for correctness and legibility.

Label adhesion strength and durability are also evaluated to ensure labels remain securely attached during normal handling and use, especially for products intended for children.

F. Packing & Packaging

Packaging inspection verifies the strength, sealing integrity, and protective performance of cartons, inner packaging, and cushioning materials to ensure products are adequately protected during transportation and storage.

Inspectors confirm the accuracy of shipping marks, warning labels, carton markings, and printed artwork. Packaging content completeness — including product quantity, accessories, and instruction manuals — is also verified.

G. Common On-Site Tests for Toy Inspection

- Carton Assortment Check

- Function Test

- Odor (Smell) Test

- Small Parts Test

- Flammability Test

- Waterproof Test

- Color Shading Check

- Stretch Test

- Fatigue Test

- Adhesive Strength Test

- Rub / Abrasion Test

- Barcode Scanning Test

$198/Man-day

From $198/Man-day for inspection everywhere in China.

Services

Request a Quote or Contact Us

By submitting this form, you agree to our Privacy Policy.